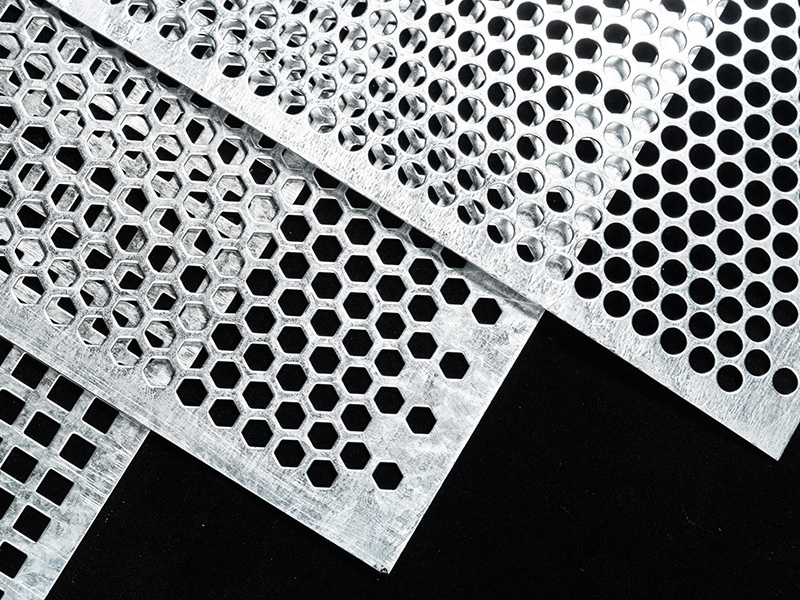

Products

Focusing On The Research And Development, Production, Sales And Technical Services Of Screening And Filtration Products.

304 316 stainless steel metal mesh

304 316 stainless steel metal mesh

304 Stainless steel mesh with dense patterns

Monofilament filter cloth (blue)

Monofilament filter cloth (black)

About

Henan Guangfeng Screening And Filtration Technology Co.,Ltd.

Annual production capacity

Professional equipment

Henan Guangfeng Screening and Filtering Technology Co., Ltd. was established in 2016, located in Xinxiang, Henan Province, which enjoys the reputation of "Battery Capital of China", "Screening and Filtering City" and "Vibration Capital". Since its establishment, we have always focused on the field of screening and filtering products, and are a comprehensive enterprise integrating research and development, production, sales and technical services.

Service Sector

We widely serve abrasive tools, electronics, food and drug processing, petrochemical industry and so on.

Blog

Welcome to our latest developments.