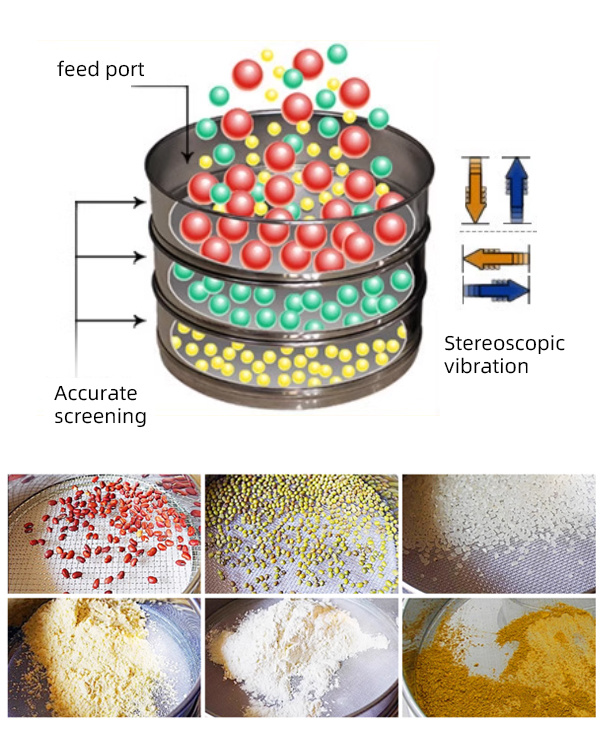

① Small particle materials fall into the lower sieve frame through the sieve holes of the upper sieve

② Large particle materials are trapped in the upper sieve mesh

③ After a set period of vibration, each layer of sieve intercepts materials within the corresponding particle size range

④ Remove the sieve frame, weigh each layer of material separately, and calculate the particle size distribution ratio (such as the percentage of material weight in a certain sieve layer to the total weight)

PRODUCTS

CONTACT

Phone: +86-373-3765418

E-mail: service@gfscreening.com

Address: No.1, Jingyi Road, Youfang Dixiang, Guandi Township, High-tech Zone, Xinxiang City, Henan Province

Sample screening laboratory specific testing

- Commodity name: Sample screening laboratory specific testing

Product Introduction

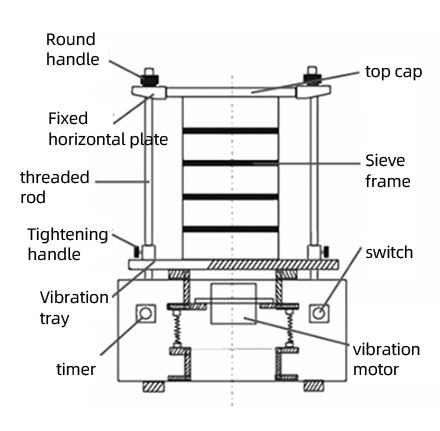

Standard test screening machine - a laboratory tool for precise screening

The standard test screening machine generates high-frequency vibrations in the vertical or horizontal direction through a vibration source (some models use three-dimensional vibration, which is a combination of vertical, horizontal, and torsional motion). The material placed inside the screening frame is subjected to vibration:

- Product Features

High screening accuracy

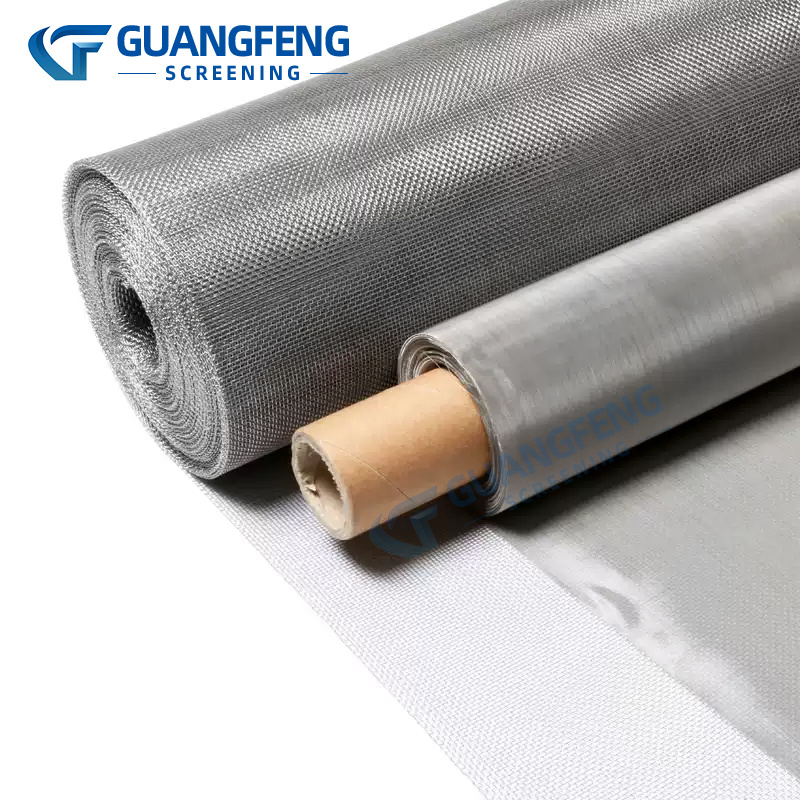

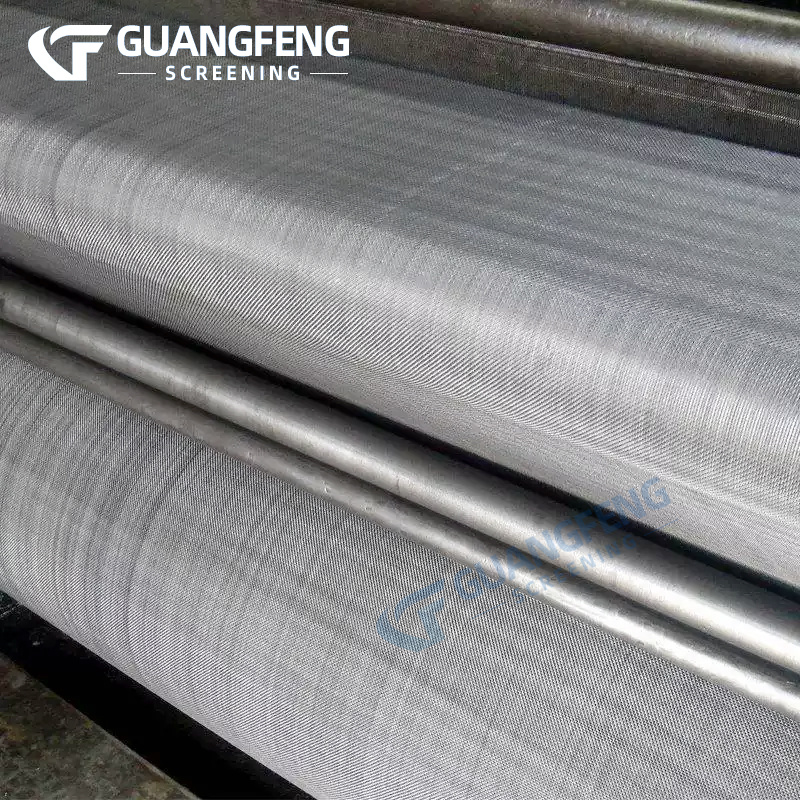

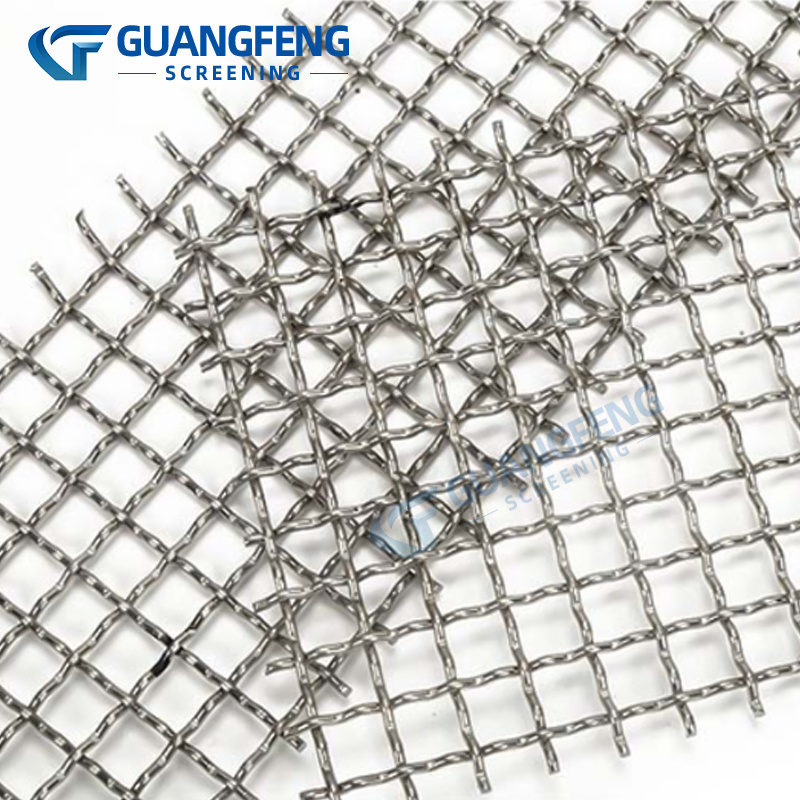

Paired with standard test sieves (sieve size in accordance with international or domestic standards, such as 1S0, ASTM, GB/T, etc.), the mesh material is mostly stainless steel (304 or 316), and the aperture error is extremely small (such as within ± 3%), ensuring the accuracy of particle size analysis.

Standard Operations

Accurate control of vibration time, frequency and other parameters can be achieved to ensure consistent test conditions and reproducible results, meeting the laboratory's requirements for data reliability

Compact

Small in size (usually desktop design), occupying less laboratory space, suitable for screening small samples (several grams to several hundred grams)

Stable operation

Reasonable design of vibration source, uniform amplitude, avoiding local accumulation of materials on the screen, and improving screening efficiency; The shock absorption system reduces the vibration interference of equipment on the surrounding environment

High safety

Some models are equipped with protective covers to prevent material splashing; The specialized models for the food and pharmaceutical industries adopt a blind spot design, which is easy to clean and meets hygiene standards such as GMP

Product parameters

mesh | Sieve size (μm) | Wire diameter d (μm) | Screening rate 0% | mesh | Sieve size (μm) | Wire diameter d (μm) | Screening rate 0% |

8# | 2360 | 1000 | 49 | 100# | 150 | 100 | 36 |

10# | 2000 | 900 | 48 | 120# | 125 | 90 | 34 |

12# | 1700 | 800 | 46 | 140# | 106 | 71 | 33 |

14# | 1400 | 710 | 44 | 160# | 95 | 63 | 36 |

16# | 1180 | 630 | 44 | 170# | 90 | 63 | 35 |

18# | 1000 | 560 | 44 | 180# | 80 | 56 | 35 |

20# | 850 | 500 | 40 | 200# | 75 | 50 | 36 |

25# | 710 | 450 | 37 | 230# | 63 | 45 | 34 |

30# | 600 | 400 | 36 | 250# | 60 | 40 | 36 |

35# | 500 | 315 | 38 | 270# | 53 | 36 | 35 |

40# | 425 | 280 | 36 | 300# | 31 | 25 | 31 |

45# | 355 | 224 | 38 | 325# | 45 | 32 | 34 |

50# | 300 | 200 | 36 | 400# | 38 | 30 | 31 |

60# | 250 | 160 | 37 | 450# | 31 | 25 | 31 |

70# | 212 | 140 | 36 | 500# | 28 | 22 | 31 |

80# | 180 | 125 | 35 | 630# | 20 | 20 | 25 |

Product Details

Usage steps

1. Determine the standard screening tool to be selected based on the inspected material and corresponding standards.

2. Stack the standard screening tools on the tray seat in ascending order of aperture, from bottom to top, and position the standard screening with grooves or positioning screws.

3. Place the inspected material into the top standard sieve (or cover the top of the standard sieve), and then press the standard sieve with the sieve head fitted on the screw column. Tighten the nut on the screw column to tighten the standard sieve. (Note: Apply consistent force on both sides and lock them with locking screws.)

4. Place the timer switch in the appropriate position (note to read the timer instructions, different settings set different times), then turn on the power switch, and the inspection screen will start working.

5. After the standard inspection sieve stops working, unscrew the nut on the screw column, move the sieve head away, and carefully remove the standard sieve tool.

6. Cut off the power supply.

Cooperative Partner

Multi layer inspection

Cooperative Partner

Keywords:

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

FAQ

Product related questions

- Material:

Q “What kind of material is used in your stainless steel screen mesh?”

A “Our screen mesh is mainly made of high quality stainless steel, such as 304, 316L, which is rust-proof, corrosion-resistant, and can be adapted to different working environments.”

- Size:

Q “What are the specifications of screen mesh? Can it be customized?”

A “We have a variety of standard specifications, such as mesh size from 10 mesh to 500 mesh, width 0.5 meters to 2 meters, etc. We can also customize special specifications according to your needs. We can also customize special specifications according to your needs.”

- Product performance:

Q “What is the filtration precision of stainless steel screen mesh?”

A “The filtration precision depends on the mesh number, the higher the mesh number, the higher the precision. For example, 100 mesh screen can filter out particles larger than about 0.15mm.”

Production and processing issues

- Production cycle:

Q “How long will it take to ship after ordering?”

A “Conventional products will be shipped within 15-20 working days after receiving the payment, and customized products will take 20-30 working days, depending on the order quantity.”

- Processing technology:

Q “How are the screens produced?”

A “We adopt advanced weaving or welding technology, through drawing, weaving, cutting, welding, surface treatment and other processes to ensure product quality.”

Application and installation issues

- Application:

Q “What industries are stainless steel screen mesh applicable to?”

A “Widely used in mining, chemical, food, pharmaceutical, construction and other industries, such as mining ore screening, chemical liquid filtration.”

- Installation method:

Q “How to install the screen?”

A “Installation needs to be based on the use of the scene and equipment to choose the appropriate method. For example, if used in vibrating screen, the screen frame should be fixed first, and then the screen mesh should be tautly fixed with special fixture.”

After-sales and service issues

- After-sales service:

Q “How can I get help if I have problems in using it?”

A “You can contact our customer service team at any time, provide product information and problem description, we will provide timely solutions.”