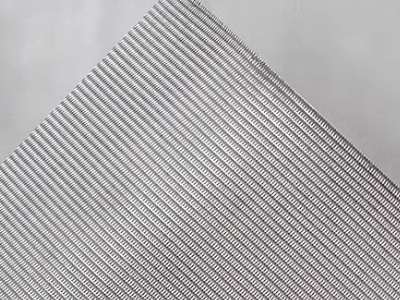

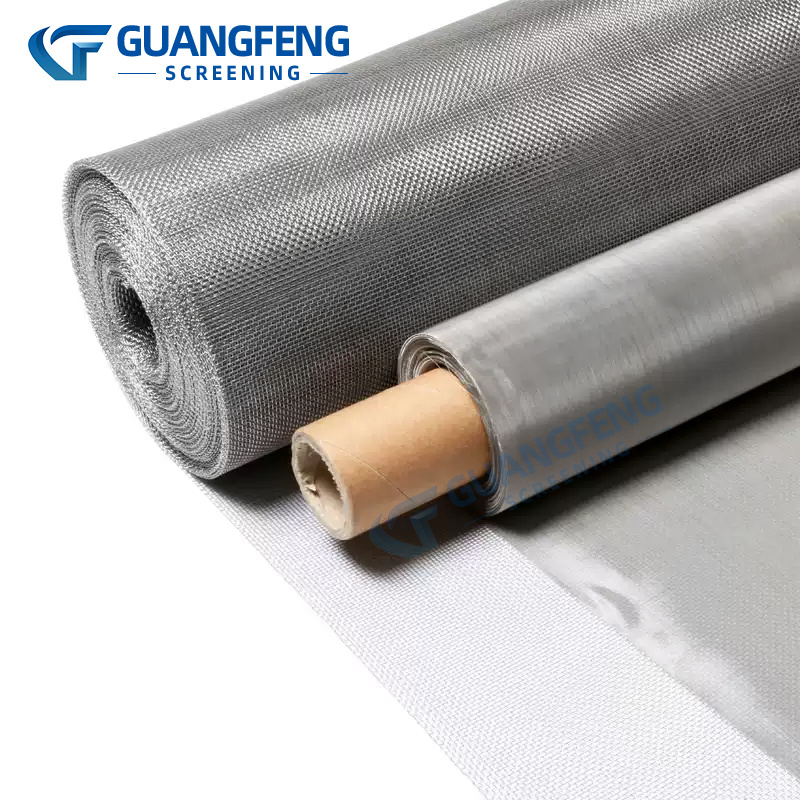

Plain weave dense mesh

PRODUCTS

CONTACT

Phone: +86-373-3765418

E-mail: service@gfscreening.com

Address: No.1, Jingyi Road, Youfang Dixiang, Guandi Township, High-tech Zone, Xinxiang City, Henan Province

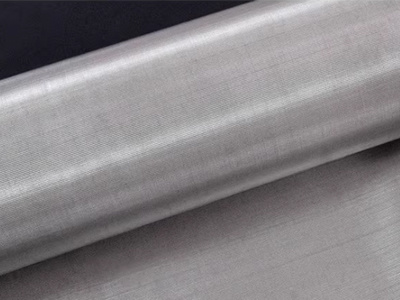

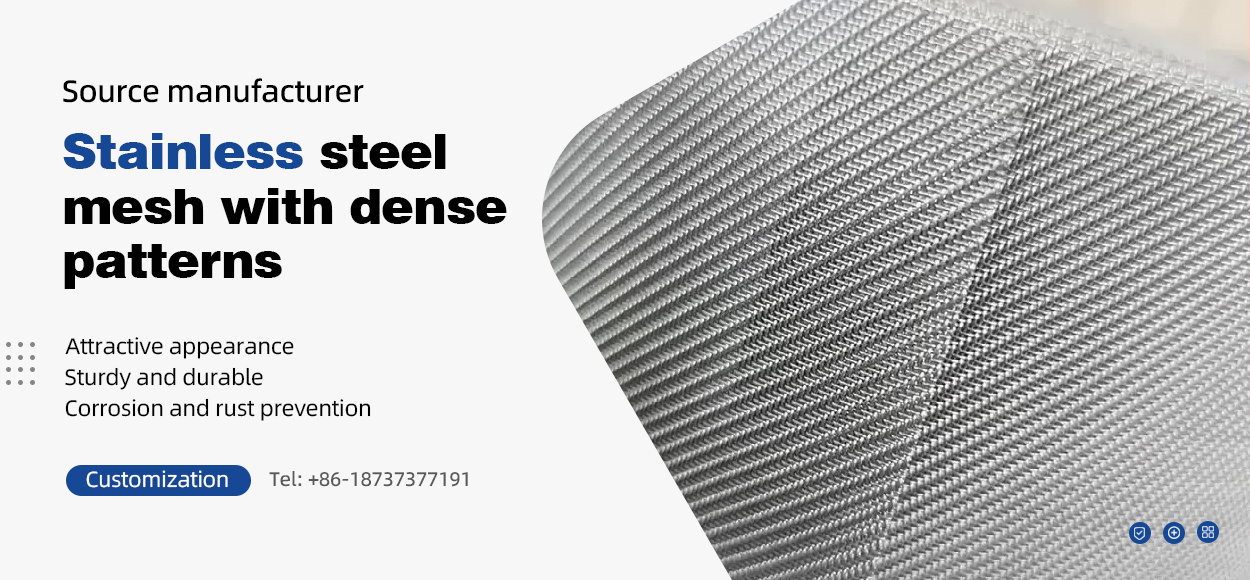

304 Stainless steel mesh with dense patterns

- Commodity name: 304 Stainless steel mesh with dense patterns

Product characteristics

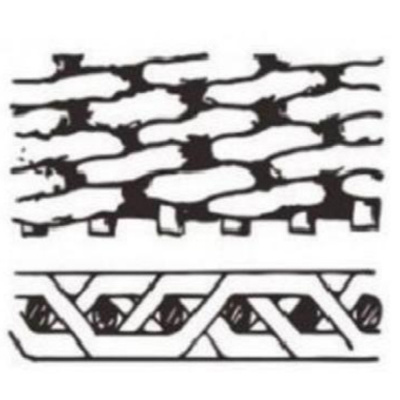

- 150 mesh dense mesh

- 300 mesh dense mesh

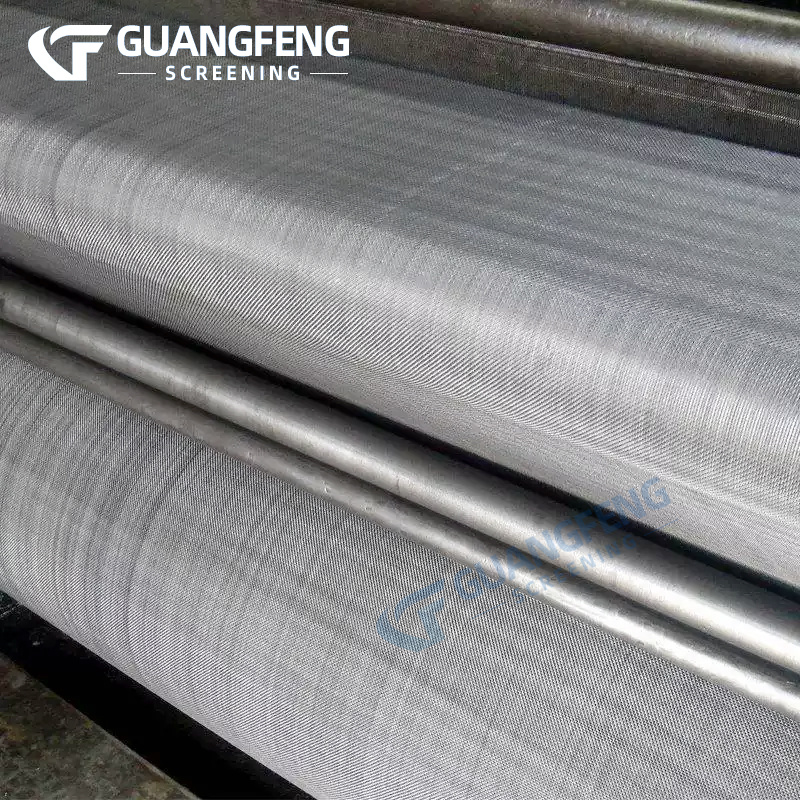

Stainless steel mesh with no visible (or slight) holes. Due to its unique weaving method, the wire diameter is several times thicker than that of square stainless steel mesh. So the stainless steel mat mesh has a thick surface and is suitable for high-pressure filtration. Its product permeability is inferior to that of perforated stainless steel mesh, but it is more wear-resistant and pressure resistant. (The higher the mesh size, the finer the texture)

Product parameters

Weaving method Can be customized according to customer requirements

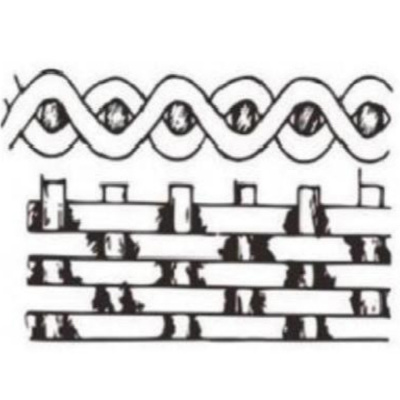

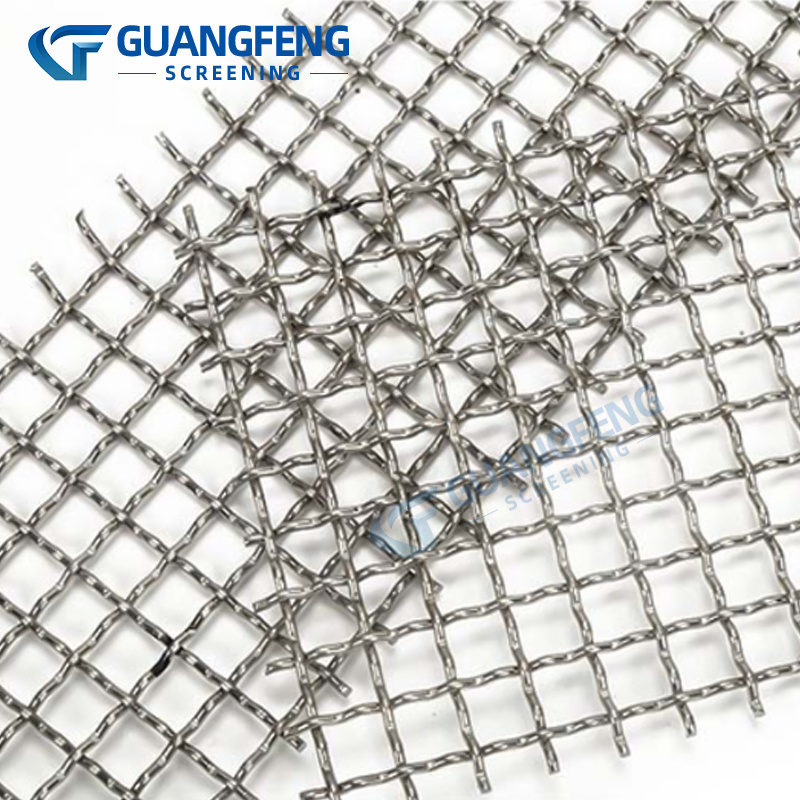

Reverse dense mesh efficient dense mesh

Reverse dense mesh, also known as high-efficiency dense mesh, has higher filtration efficiency, strong absorption properties, and backwashing ability. It has a wide range of applications in industries such as sewage treatment, coal mining, petroleum, chemical, food, and medicine.

Mesh NO. | Specifications | Nowinal aperture(μm) | Net thickness (mm) | Mesh NO. | Specifications | Nowinal aperture(μm) | Net thickness (mm) |

MPW23 | 118x740/0.063x0.036 | 23 | 0.135 | MPW97 | 24x110/0.355x0.25 | 97 | 0.855 |

MPW23 | 100x1200/0.063x0.023 | 23 | 0.109 | MPW100 | 25x140/0.28x0.2 | 100 | 0.680 |

MPW32 | 80x400/0.125x0.063 | 32 | 0.251 | MPW115 | 22x120/0.315x0.224 | 115 | 0.763 |

MPW35 | 70x340/0.125x0.08 | 35 | 0.285 | MPW126 | 20x110/0.355x0.25 | 126 | 0.855 |

MPW36 | 65x770/0.1x0.036 | 36 | 0.172 | MPW130 | 20x160/0.25x0.16 | 130 | 0.570 |

MPW37 | 70x390/0.112x0.071 | 37 | 0.254 | MPW133 | 20x140/0.315x0.2 | 133 | 0. 715 |

MPW37 | 80x620/0.1x0.045 | 37 | 0. 190 | MPW145 | 16x120/0.28x0.224 | 145 | 0. 728 |

MPW38 | 77x560/0.14x0.05 | 38 | 0.240 | MPW155 | 17.2x120/0.355x0.224 | 155 | 0.803 |

MPW39 | 60x270/0.14x0.1 | 39 | 0. 340 | MPW160 | 16x100/0.4x0.28 | 160 | 0.960 |

MPW40 | 80x700/0.125x0.04 | 40 | 0.206 | MPW173 | 14x76/0.45x0.355 | 173 | 1. 160 |

MPW41 | 60x300/0.14x0.09 | 41 | 0.320 | MPW177 | 14x110/0.355x0.25 | 177 | 0.855 |

MPW42 | 65x400/0.125x0.071 | 42 | 0.267 | MPW182 | 14X100/0.4X0.28 | 182 | 0. 960 |

MPW30 | 70x930/0.1x0.03 | 30 | 0.160 | MPW192 | 12.7x76/0.45x0.355 | 192 | 1.160 |

MPW50 | 50x270/0.14x0.1 | 50 | 0.340 | MPW211 | 12x64/0.56x0.4 | 211 | 1. 360 |

MPW51 | 60x500/0.14x0.056 | 51 | 0.252 | MPW211 | 12x86/0.45x0.315 | 211 | 1.080 |

MPW55 | 50x280/0.16x0.09 | 55 | 0.340 | MPW248 | 10x76/0.5x0.355 | 248 | 1.210 |

MPW56 | 45x250/0.16x0.112 | 56 | 0. 384 | MPW249 | 10x90/0.45x0.28 | 249 | 1. 010 |

MPW63 | 40x200/0.18x0.125 | 63 | 0.430 | MPW275 | 8x85/0.45x0.315 | 275 | 1.080 |

MPW69 | 35x170/0.224x0.16 | 69 | 0.544 | MPW296 | 8.5x60/0.63x0.45 | 296 | 1.530 |

MPW74 | 35x190/0.224x0.14 | 74 | 0.504 | MPW310 | 18x45/0.8x0.6 | 310 | 2. 000 |

MPW77 | 30x140/0.315x0.2 | 77 | 0.715 | MPW319 | 7.2x44/0. 71x0.63 | 319 | 1.970 |

MPW82 | 30x150/0.25x0.18 | 82 | 0.610 | MPW347 | 7x40/0.9x0.71 | 347 | 2. 320 |

MPW92 | 28x150/0.28x0.18 | 92 | 0.640 | MPW500 | 5x32/1.25x0.9 | 500 | 3.05 |

Product parameters

Product parameters

*Stainless steel wire mesh is widely used in daily use, petroleum, and chemical industries.

*Classification, screening, and screening of solids, liquids, and gases in the fields of food, pharmaceuticals, mining, metallurgy, aerospace, and machinery manufacturing.

*Any other mesh size can be customized for production according to your requirements.a

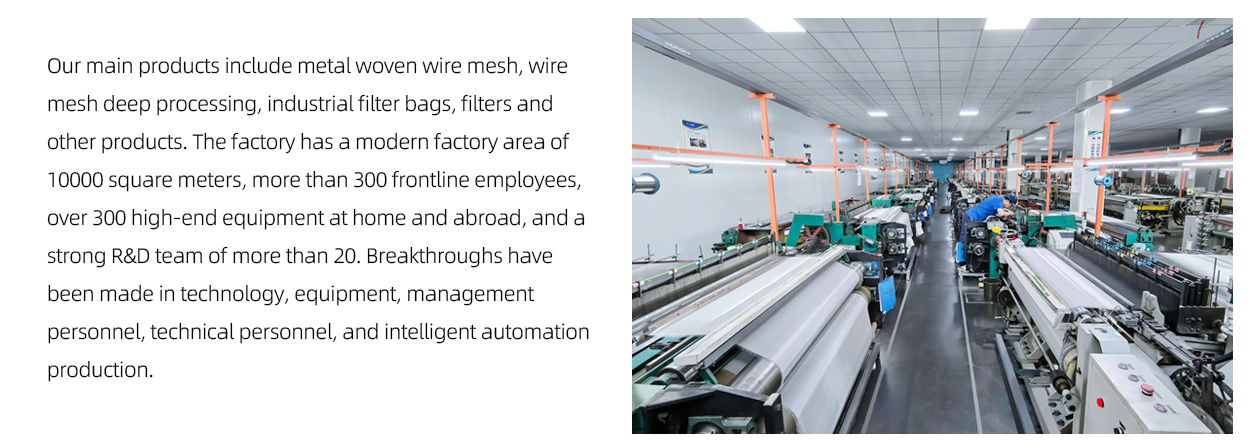

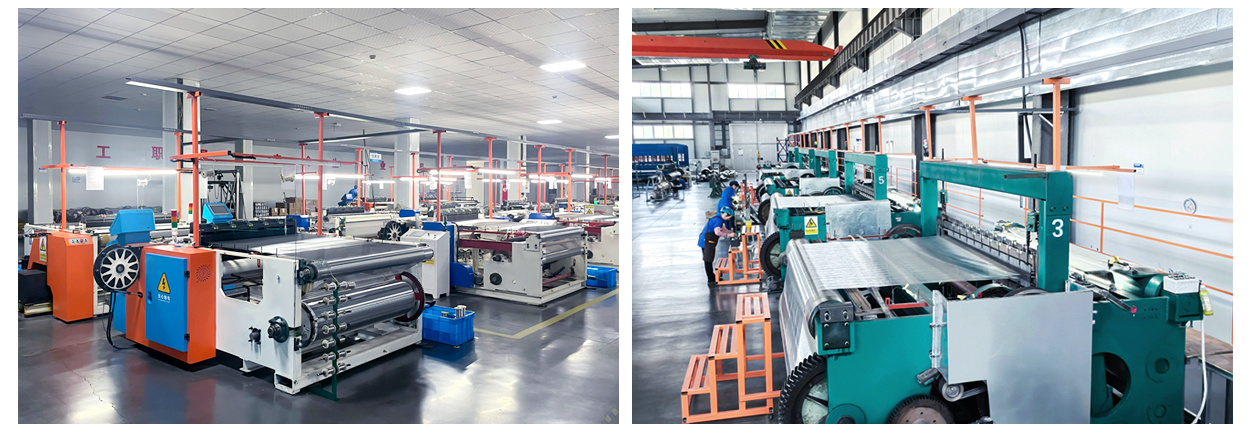

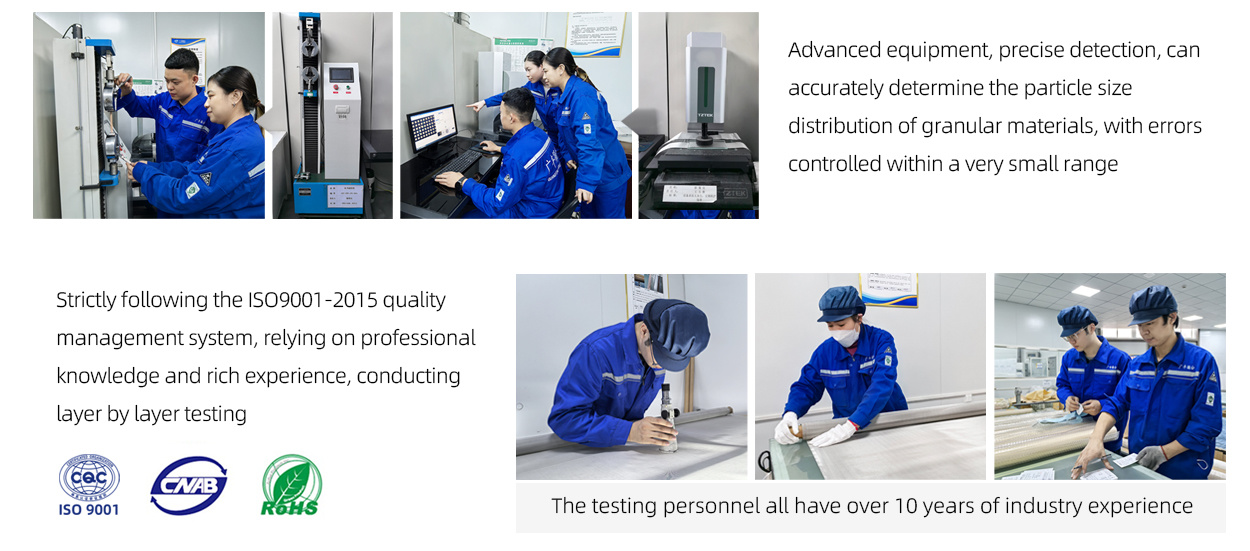

Manufacturer's strength

Multi layer inspection

Keywords:

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

FAQ

Product related questions

- Material:

Q “What kind of material is used in your stainless steel screen mesh?”

A “Our screen mesh is mainly made of high quality stainless steel, such as 304, 316L, which is rust-proof, corrosion-resistant, and can be adapted to different working environments.”

- Size:

Q “What are the specifications of screen mesh? Can it be customized?”

A “We have a variety of standard specifications, such as mesh size from 10 mesh to 500 mesh, width 0.5 meters to 2 meters, etc. We can also customize special specifications according to your needs. We can also customize special specifications according to your needs.”

- Product performance:

Q “What is the filtration precision of stainless steel screen mesh?”

A “The filtration precision depends on the mesh number, the higher the mesh number, the higher the precision. For example, 100 mesh screen can filter out particles larger than about 0.15mm.”

Production and processing issues

- Production cycle:

Q “How long will it take to ship after ordering?”

A “Conventional products will be shipped within 15-20 working days after receiving the payment, and customized products will take 20-30 working days, depending on the order quantity.”

- Processing technology:

Q “How are the screens produced?”

A “We adopt advanced weaving or welding technology, through drawing, weaving, cutting, welding, surface treatment and other processes to ensure product quality.”

Application and installation issues

- Application:

Q “What industries are stainless steel screen mesh applicable to?”

A “Widely used in mining, chemical, food, pharmaceutical, construction and other industries, such as mining ore screening, chemical liquid filtration.”

- Installation method:

Q “How to install the screen?”

A “Installation needs to be based on the use of the scene and equipment to choose the appropriate method. For example, if used in vibrating screen, the screen frame should be fixed first, and then the screen mesh should be tautly fixed with special fixture.”

After-sales and service issues

- After-sales service:

Q “How can I get help if I have problems in using it?”

A “You can contact our customer service team at any time, provide product information and problem description, we will provide timely solutions.”