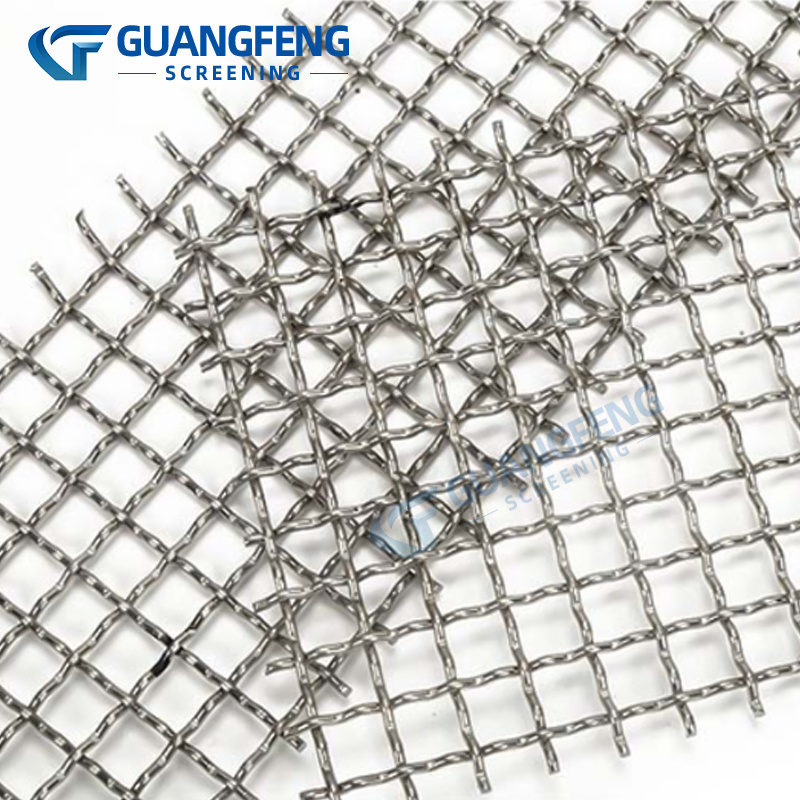

Resistant to rust Preferred stainless steel material for rust resistance

PRODUCTS

CONTACT

Phone: +86-373-3765418

E-mail: service@gfscreening.com

Address: No.1, Jingyi Road, Youfang Dixiang, Guandi Township, High-tech Zone, Xinxiang City, Henan Province

Stainless steel filter screen

- Commodity name: Stainless steel filter screen

Product characteristics

- Excellent filtering performance

It can exhibit uniform surface filtration performance for filter particle sizes ranging from 2-800 μ m, effectively removing solid particles ranging from 0.02-100 μ m. It is suitable for situations where the particles in the suspension are very small and the content is minimal, with a general solid content not exceeding 0.01%.

- Excellent material performance

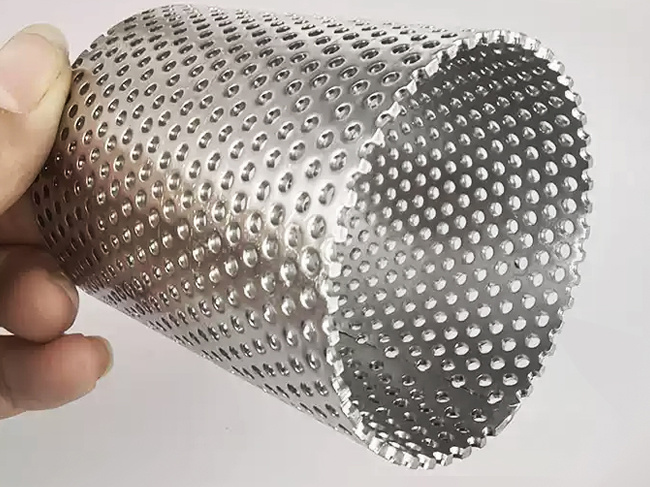

The production materials include outer galvanized iron punched mesh, stainless steel punched mesh, copper punched mesh, etc. Among them, stainless steel punched mesh is the most widely used. These materials endow the filter cartridge with excellent corrosion resistance, heat resistance, pressure resistance, and wear resistance.

- Accurate filtering precision

By precisely controlling the diameter of the pore, precise filtration accuracy is ensured, which can effectively intercept target impurities.

- High traffic characteristics

The large flow rate per unit area can meet large-scale filtration needs and improve production efficiency.

- Wide temperature adaptability

Capable of adapting to low and high temperature environments, with a wide working temperature range, without affecting its filtration performance.

Craftsmanship

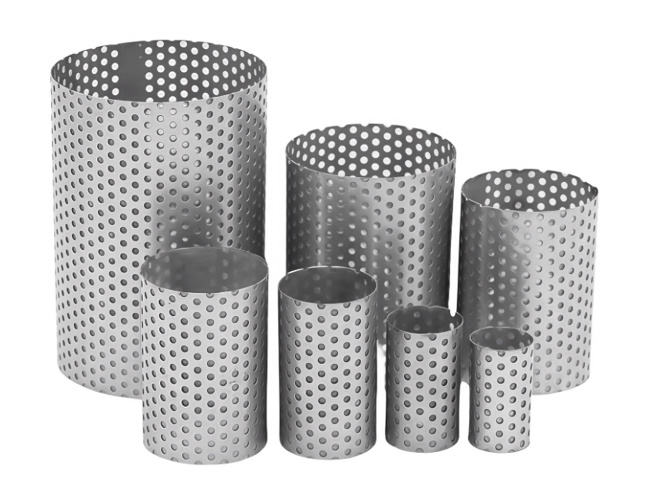

Specification and Style Display

Diverse specifications and models, can be customized according to customer requirements for processing

Application area

Petrochemical industry:It is used in distillation, absorption, evaporation and filtration processes in petrochemical production to remove impurities and foam mixed in gas and liquid, and ensure smooth production process and product quality.

Oil field pipeline: During the process of oil field extraction and transportation, the crude oil, natural gas, etc. in the pipeline are filtered to prevent impurities from damaging the pipeline and equipment.

Refueling equipment and construction machinery: providing reliable guarantee for fuel filtration of refueling equipment and construction machinery, ensuring fuel cleanliness, reducing engine wear, and extending equipment service life.

Water treatment: effectively removes fine suspended particles and colloidal substances that cannot be removed by ordinary sand filtration, widely used in fields such as drinking water purification and sewage treatment to improve water quality。

Pharmaceutical and food processing: Meet the strict requirements of the pharmaceutical and food processing industries for filtration accuracy and hygiene safety, ensure that products meet quality standards, and safeguard consumer health.

Cooperative Partner

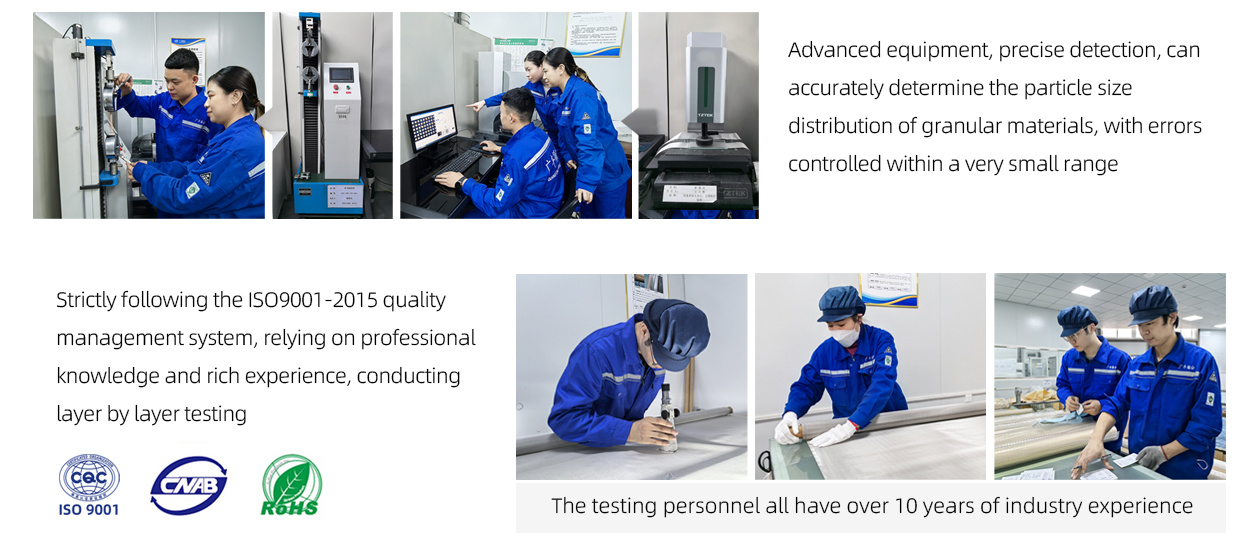

Multi layer inspection

Cooperative Partner

Keywords:

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

FAQ

Product related questions

- Material:

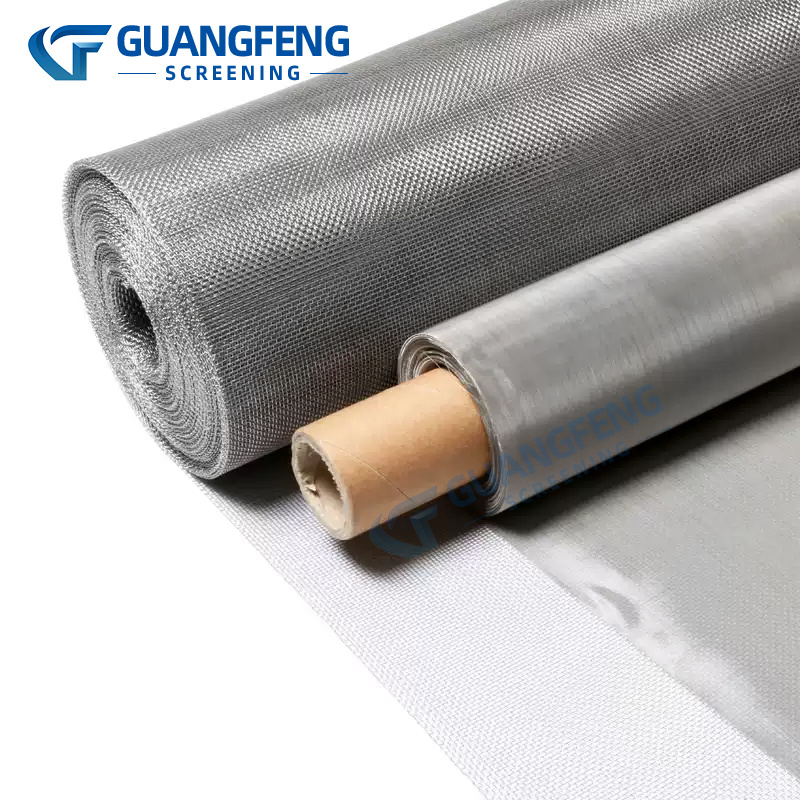

Q “What kind of material is used in your stainless steel screen mesh?”

A “Our screen mesh is mainly made of high quality stainless steel, such as 304, 316L, which is rust-proof, corrosion-resistant, and can be adapted to different working environments.”

- Size:

Q “What are the specifications of screen mesh? Can it be customized?”

A “We have a variety of standard specifications, such as mesh size from 10 mesh to 500 mesh, width 0.5 meters to 2 meters, etc. We can also customize special specifications according to your needs. We can also customize special specifications according to your needs.”

- Product performance:

Q “What is the filtration precision of stainless steel screen mesh?”

A “The filtration precision depends on the mesh number, the higher the mesh number, the higher the precision. For example, 100 mesh screen can filter out particles larger than about 0.15mm.”

Production and processing issues

- Production cycle:

Q “How long will it take to ship after ordering?”

A “Conventional products will be shipped within 15-20 working days after receiving the payment, and customized products will take 20-30 working days, depending on the order quantity.”

- Processing technology:

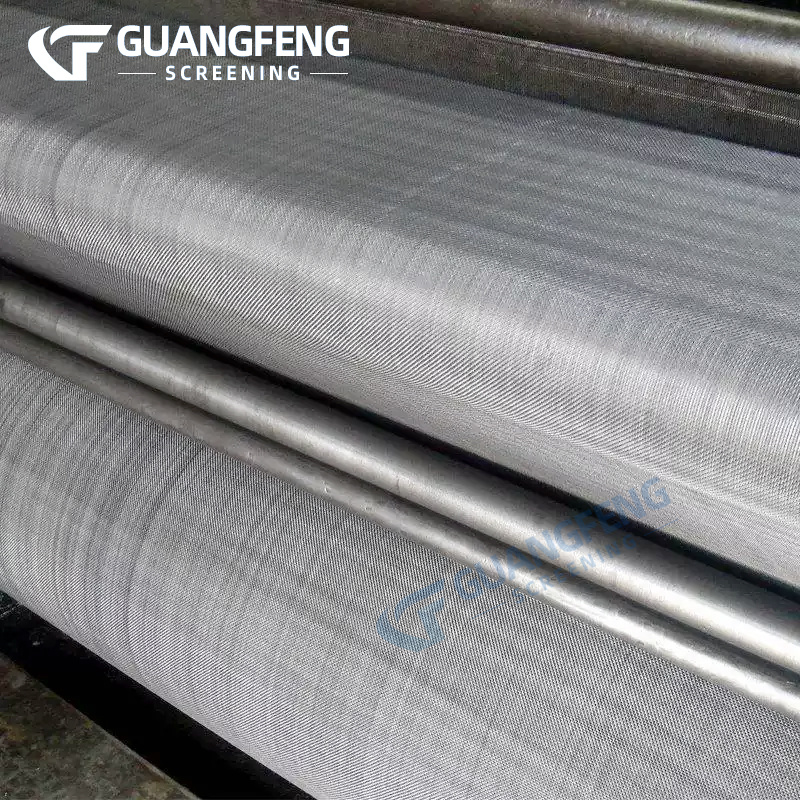

Q “How are the screens produced?”

A “We adopt advanced weaving or welding technology, through drawing, weaving, cutting, welding, surface treatment and other processes to ensure product quality.”

Application and installation issues

- Application:

Q “What industries are stainless steel screen mesh applicable to?”

A “Widely used in mining, chemical, food, pharmaceutical, construction and other industries, such as mining ore screening, chemical liquid filtration.”

- Installation method:

Q “How to install the screen?”

A “Installation needs to be based on the use of the scene and equipment to choose the appropriate method. For example, if used in vibrating screen, the screen frame should be fixed first, and then the screen mesh should be tautly fixed with special fixture.”

After-sales and service issues

- After-sales service:

Q “How can I get help if I have problems in using it?”

A “You can contact our customer service team at any time, provide product information and problem description, we will provide timely solutions.”