PRODUCTS

CONTACT

Phone: +86-373-3765418

E-mail: service@gfscreening.com

Address: No.1, Jingyi Road, Youfang Dixiang, Guandi Township, High-tech Zone, Xinxiang City, Henan Province

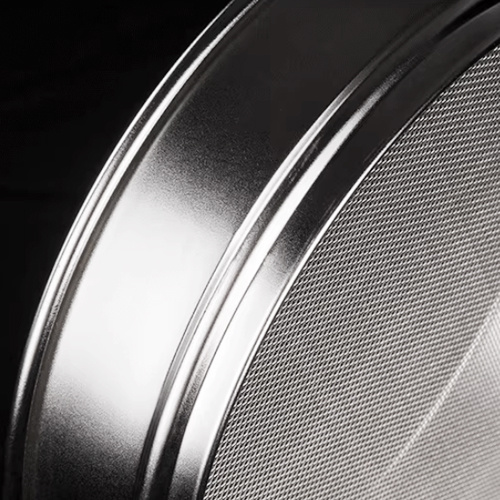

Standard test sieve

- Commodity name: Standard test sieve

Product characteristics

Multiple uses to choose from, not just for household use

Grains:

Red beans 5mesh, black beans 5mesh, soybeans 5mesh, mung beans 10mesh, job's tears 8meshblack rice 14mesh, brown rice 14mesh, rice 12mesh-14mesh, millet 20mesh, wheat 12mesh, oatkernels 14mesh, cassia seeds 16mesh, crushed corn 16mesh, sesame seeds 20mesh

Powders:

fried chicken flour 10mesh-30mesh, corn flour 30mesh, almond flour 30mesh, cereals30mesh-40mesh, flour, mung bean flour, sesame flour 50mesh-60mesh, traditional Chinesemedicine powder 80mesh (coarser 40mesh-60mesh, oral 60mesh-80mesh), fine Chinese medicinefacial mask powder 100mesh-120mesh, intestines powder 60mesh, sangi powder 80mesh-100meshpearl powder 120mesh-150mesh, pine pollen 80mesh-150mesh, coffee powder 100mesh-120mesh

Liquids:

soybean milk, honey 6mesh-120mesh, medicine residue, soup residue, tea water 80mesh-150mesh,edible oil, machinery oil residue 150mesh-200mesh

Other categories:

yellow mealworm egg laying sieve 12mesh, insect feces 30mesh, cat litter 30mesh, butterfly surface50mesh, Sichuan pepper 6mesh, chili seeds 8-10 mesh, soil 10-50 mesh

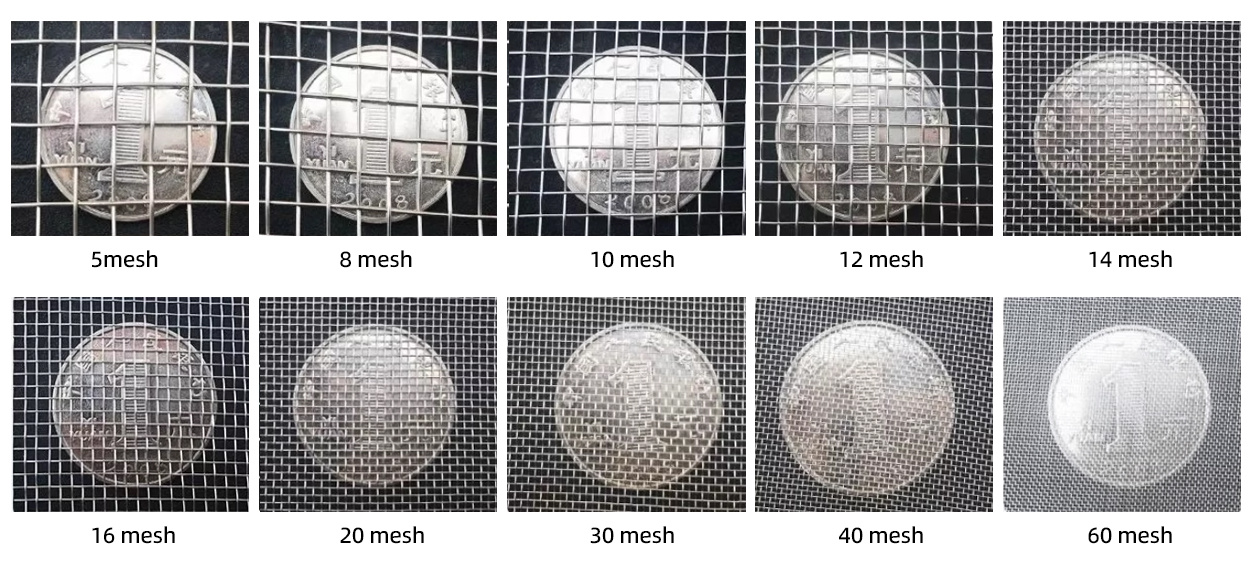

Comparison Table of Mesh Size of Wire Mesh

mesh | Sieve size (μm) | Wire diameter d (μm) | Screening rate 0% | mesh | Sieve size (μm) | Wire diameter d (μm) | Screening rate 0% |

8# | 2360 | 1000 | 49 | 100# | 150 | 100 | 36 |

10# | 2000 | 900 | 48 | 120# | 125 | 90 | 34 |

12# | 1700 | 800 | 46 | 140# | 106 | 71 | 33 |

14# | 1400 | 710 | 44 | 160# | 95 | 63 | 36 |

16# | 1180 | 630 | 44 | 170# | 90 | 63 | 35 |

18# | 1000 | 560 | 44 | 180# | 80 | 56 | 35 |

20# | 850 | 500 | 40 | 200# | 75 | 50 | 36 |

25# | 710 | 450 | 37 | 230# | 63 | 45 | 34 |

30# | 600 | 400 | 36 | 250# | 60 | 40 | 36 |

35# | 500 | 315 | 38 | 270# | 53 | 36 | 35 |

40# | 425 | 280 | 36 | 300# | 31 | 25 | 31 |

45# | 355 | 224 | 38 | 325# | 45 | 32 | 34 |

50# | 300 | 200 | 36 | 400# | 38 | 30 | 31 |

60# | 250 | 160 | 37 | 450# | 31 | 25 | 31 |

70# | 212 | 140 | 36 | 500# | 28 | 22 | 31 |

80# | 180 | 125 | 35 | 630# | 20 | 20 | 25 |

Display of Common Contents

Product Photograph

Usage and Application Fields

Granularity analysis:

Used to determine the particle size composition of granular and powdery materials, determine the distribution of particles of different sizes, widely used in industries such as abrasives, metallurgy, and building materials. For example, in the abrasive industry, the size distribution of abrasive particles can be determined through standard test sieves to ensure the quality and performance of abrasives.

Material screening:

To achieve graded screening of materials and separate particles of different sizes, it can be used in chemical, mining and other fields to screen ores, chemical raw materials, etc. to meet the requirements of different production processes.

Quality Control:

In industries such as pharmaceuticals and food, it is used for particle size detection and screening of raw materials and products to ensure that product quality meets standard requirements. For example, in the pharmaceutical industry, there are strict requirements for the particle size of drug powders, and standard test sieves can be used to detect and control the particle size of drug powders.

Cooperative Partner

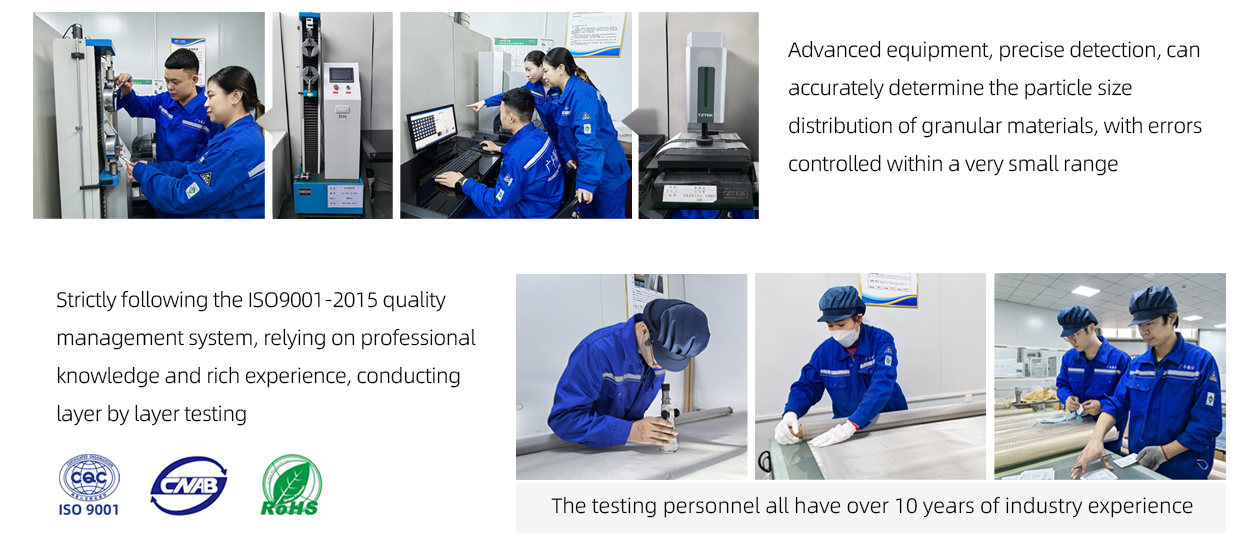

Multi layer inspection

Cooperative Partner

Keywords:

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

FAQ

Product related questions

- Material:

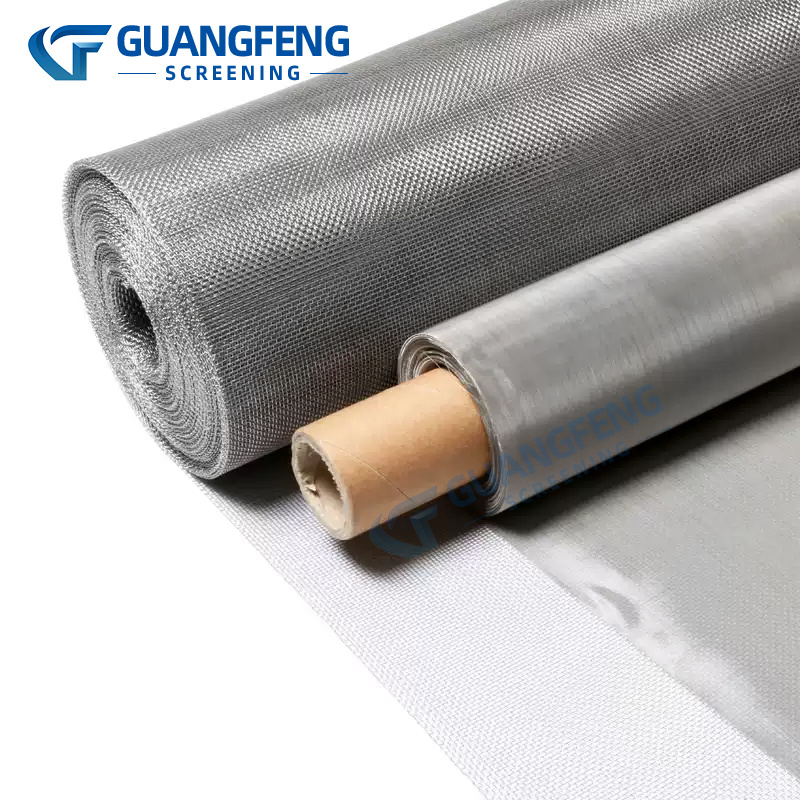

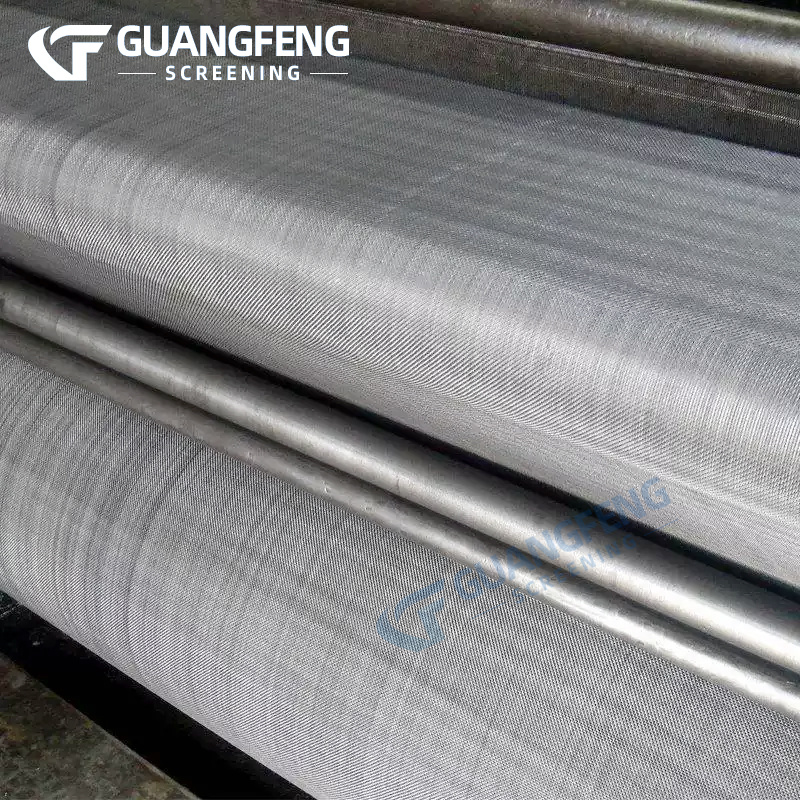

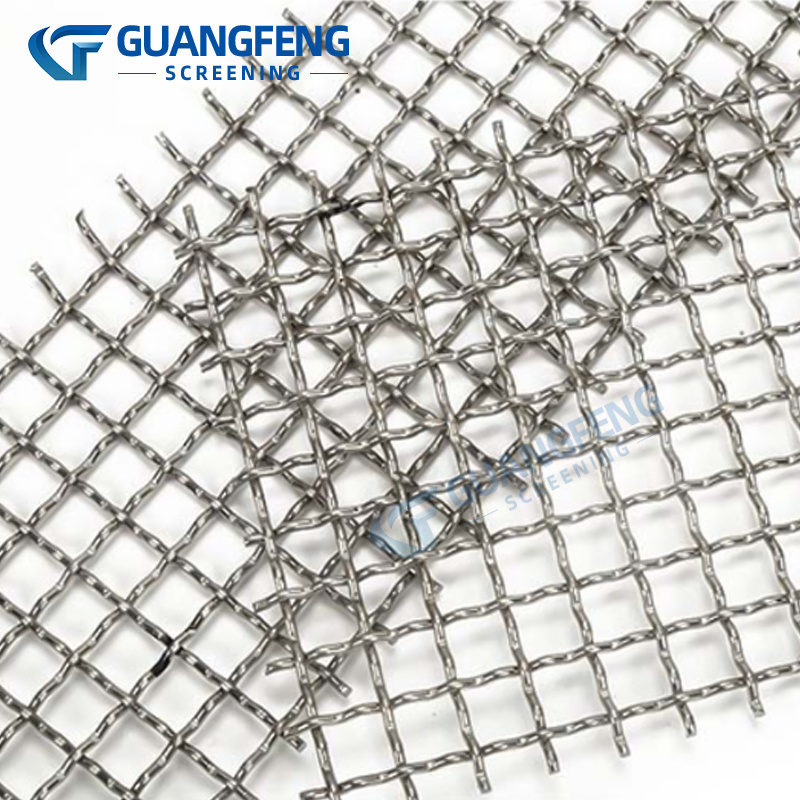

Q “What kind of material is used in your stainless steel screen mesh?”

A “Our screen mesh is mainly made of high quality stainless steel, such as 304, 316L, which is rust-proof, corrosion-resistant, and can be adapted to different working environments.”

- Size:

Q “What are the specifications of screen mesh? Can it be customized?”

A “We have a variety of standard specifications, such as mesh size from 10 mesh to 500 mesh, width 0.5 meters to 2 meters, etc. We can also customize special specifications according to your needs. We can also customize special specifications according to your needs.”

- Product performance:

Q “What is the filtration precision of stainless steel screen mesh?”

A “The filtration precision depends on the mesh number, the higher the mesh number, the higher the precision. For example, 100 mesh screen can filter out particles larger than about 0.15mm.”

Production and processing issues

- Production cycle:

Q “How long will it take to ship after ordering?”

A “Conventional products will be shipped within 15-20 working days after receiving the payment, and customized products will take 20-30 working days, depending on the order quantity.”

- Processing technology:

Q “How are the screens produced?”

A “We adopt advanced weaving or welding technology, through drawing, weaving, cutting, welding, surface treatment and other processes to ensure product quality.”

Application and installation issues

- Application:

Q “What industries are stainless steel screen mesh applicable to?”

A “Widely used in mining, chemical, food, pharmaceutical, construction and other industries, such as mining ore screening, chemical liquid filtration.”

- Installation method:

Q “How to install the screen?”

A “Installation needs to be based on the use of the scene and equipment to choose the appropriate method. For example, if used in vibrating screen, the screen frame should be fixed first, and then the screen mesh should be tautly fixed with special fixture.”

After-sales and service issues

- After-sales service:

Q “How can I get help if I have problems in using it?”

A “You can contact our customer service team at any time, provide product information and problem description, we will provide timely solutions.”