PRODUCTS

CONTACT

Phone: +86-373-3765418

E-mail: service@gfscreening.com

Address: No.1, Jingyi Road, Youfang Dixiang, Guandi Township, High-tech Zone, Xinxiang City, Henan Province

Rotary Vibrating Screen

- Commodity name: Rotary Vibrating Screen

Core Advantages: Precise Sieving, High Efficiency & Stability

Guangfeng Screening’s Rotary Vibrating Screen is an efficient and precise multi-layer vibrating screening equipment, designed to meet the needs of classification, impurity removal, and filtration for powders, granules, liquids, and other materials. Adopting a unique three-dimensional vibration principle, the centrifugal force generated by the eccentric blocks at both ends of the motor causes the screen surface to produce multi-dimensional composite vibrations (horizontal, vertical, and inclined), significantly improving material screening efficiency and accuracy.

Technical Features: Quality Reflected in Details

working principle

The rotary vibrating screen uses an upright motor as the excitation source, and eccentric weights are installed on the motor shaft to convert the motor's rotational motion into horizontal, vertical, and inclined three-dimensional motion. This motion is then transmitted to the screen surface through the shock-absorbing effect of springs, allowing the material to undergo outward expansion involute motion on the screen surface. Adjusting the phase angle of the heavy hammers at the upper and lower ends can change the motion trajectory of the material on the screen surface, thereby achieving precision screening, probability screening, and so on of the material.

The rotary vibrating screen uses an upright motor as the excitation source, and eccentric weights are installed on the motor shaft to convert the motor's rotational motion into horizontal, vertical, and inclined three-dimensional motion. This motion is then transmitted to the screen surface through the shock-absorbing effect of springs, allowing the material to undergo outward expansion involute motion on the screen surface. Adjusting the phase angle of the heavy hammers at the upper and lower ends can change the motion trajectory of the material on the screen surface, thereby achieving precision screening, probability screening, and so on of the material.

Detail Display

The rotary vibrating screen is mainly composed of a screen cover, screen frame, vibration motor, shock-absorbing spring, base, etc.

The screen cover is composed of a feed inlet and an inclined cone, and its lower end is connected to the screen frame. The screen cover and the screen frame are connected by a snap ring, and there is a sealing gasket between the screen cover and the screen frame. The screen frame is made of welded steel plates, with a receiving ring at both the upper and lower ends, and a flange ring inside for fixing the screen components and other structures.

The vibration source consists of a vertical vibration motor, a motor base bracket, and a vibration transmitting body.

The shock absorber spring consists of a spring, a spring support (with internal threads on one end of a steel cylinder), screws, and spring washers. There are 12-20 shock-absorbing springs along one circle of the vibrating body.

The base is made of rolled and welded steel plates, and there is a maintenance door and an electrical switch seat on the base wall.

Detail Display

Product Parameters

model | Effective screening diameter (mm) | Effective screening area (m2) | layers | power(Kw) | |

|---|---|---|---|---|---|

Vibration Motor | Machine ordinary electricity | ||||

XZS-400 | Φ340 | 0.0907 |

| 0.18 |

|

XZS-600 | Φ540 | 0.2289 | 1-5 | 0.25 |

|

XZS-800 | Φ730 | 0.4183 | 1-5 | 0.55 | 1.1 |

XZS-1000 | Φ900 | 0.6359 | 1-5 | 1.1 | 1.5 |

XZS-1200 | Φ1100 | 0.9499 | 1-5 | 1.1 | 1.5 |

XZS-1500 | Φ1400 | 1.5386 | 1-5 | 1.5 | 2.2 |

XZS-1800 | Φ1700 | 2.2687 | 1-3 | 2.2 | 3.00 |

XZS-2000 | Φ1886 | 2.7922 | 1-3 | 2.2 | 3.00 |

Application Scenarios: Trusted in Multiple Fields

- Food industry: screening and filtration of sugar powder, starch, salt, Rice noodles, milk powder, soybean milk, egg powder, soy sauce, fruit juice, etc.

- Chemical industry: Processing of materials such as resins, coatings, industrial drugs, cosmetics, paints, and traditional Chinese medicine powders.

- Metal and metallurgical mining: screening and grading of aluminum powder, lead powder, copper powder, ore, alloy powder, welding rod powder, manganese dioxide, electrolytic copper powder, etc.

- Pollution treatment: can be used for the treatment of waste oil, wastewater, dyeing and finishing wastewater, additives, activated carbon, etc.

Keywords:

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

FAQ

Product related questions

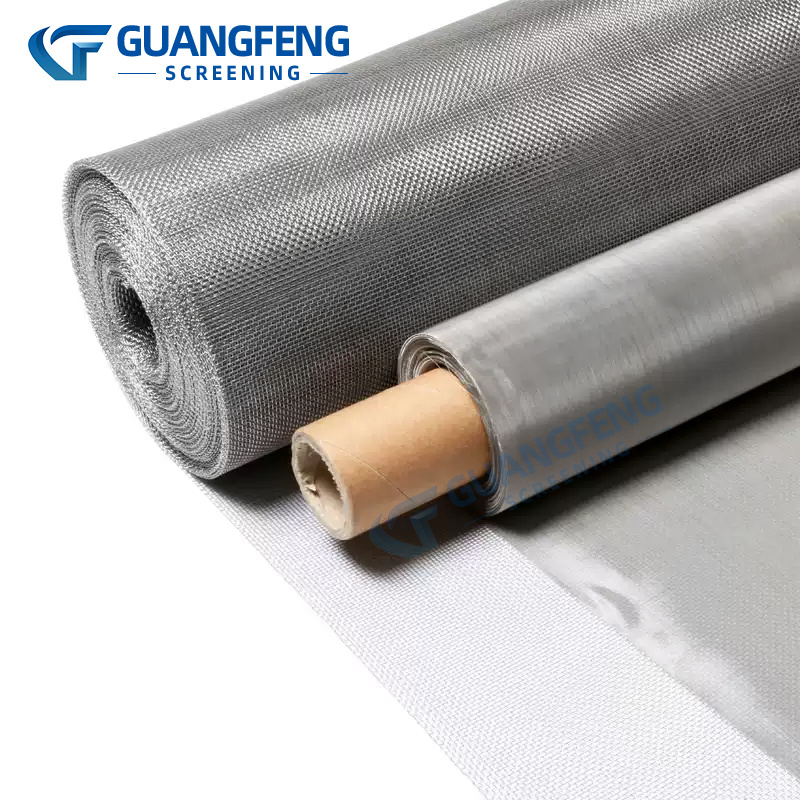

- Material:

Q “What kind of material is used in your stainless steel screen mesh?”

A “Our screen mesh is mainly made of high quality stainless steel, such as 304, 316L, which is rust-proof, corrosion-resistant, and can be adapted to different working environments.”

- Size:

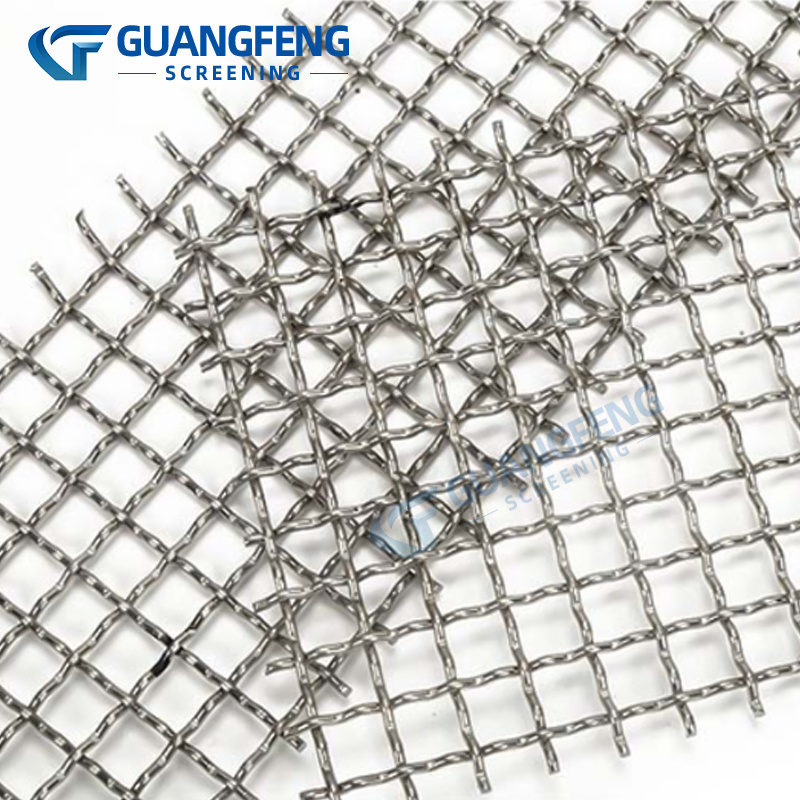

Q “What are the specifications of screen mesh? Can it be customized?”

A “We have a variety of standard specifications, such as mesh size from 10 mesh to 500 mesh, width 0.5 meters to 2 meters, etc. We can also customize special specifications according to your needs. We can also customize special specifications according to your needs.”

- Product performance:

Q “What is the filtration precision of stainless steel screen mesh?”

A “The filtration precision depends on the mesh number, the higher the mesh number, the higher the precision. For example, 100 mesh screen can filter out particles larger than about 0.15mm.”

Production and processing issues

- Production cycle:

Q “How long will it take to ship after ordering?”

A “Conventional products will be shipped within 15-20 working days after receiving the payment, and customized products will take 20-30 working days, depending on the order quantity.”

- Processing technology:

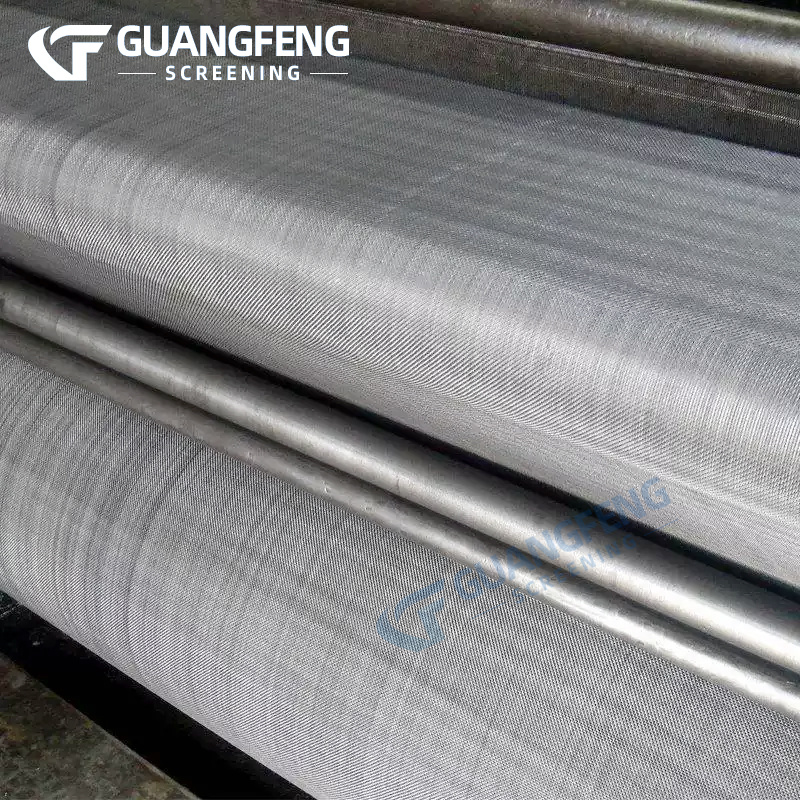

Q “How are the screens produced?”

A “We adopt advanced weaving or welding technology, through drawing, weaving, cutting, welding, surface treatment and other processes to ensure product quality.”

Application and installation issues

- Application:

Q “What industries are stainless steel screen mesh applicable to?”

A “Widely used in mining, chemical, food, pharmaceutical, construction and other industries, such as mining ore screening, chemical liquid filtration.”

- Installation method:

Q “How to install the screen?”

A “Installation needs to be based on the use of the scene and equipment to choose the appropriate method. For example, if used in vibrating screen, the screen frame should be fixed first, and then the screen mesh should be tautly fixed with special fixture.”

After-sales and service issues

- After-sales service:

Q “How can I get help if I have problems in using it?”

A “You can contact our customer service team at any time, provide product information and problem description, we will provide timely solutions.”