PRODUCTS

CONTACT

Phone: +86-373-3765418

E-mail: service@gfscreening.com

Address: No.1, Jingyi Road, Youfang Dixiang, Guandi Township, High-tech Zone, Xinxiang City, Henan Province

Square Swing Screen

- Commodity name: Square Swing Screen

Core Advantages: Square Structure, Enhanced Efficiency

Guangfeng Sieving's Square Swing Screen takes a large-sized square screen surface as its core design, integrated with a manual-simulating 3D swinging trajectory. Compared with circular swing screens, its effective screening area is increased by over 40%, which enables continuous screening operations for multiple materials with high output. The equipment meets the grading and impurity removal needs of materials with different particle sizes, and it also features high screening accuracy and low material clogging rate, providing an efficient solution for large-scale production.

Technical Features: Quality Reflected in Details

working principle

From the perspective of the motion trajectory of the shaking body or screening box of the screening machine, the square swinging screen, also known as the arc-shaped screen, generates an inertial force with a certain regularity in direction around a fixed axis due to the vibration force generated by its driving device. Its essence is the reciprocating inertial force formed by the rotation of the eccentric wheel around the fixed axis. According to the structural characteristics and working principle of the square oscillating vibrating screen, its screen surface is generally arranged horizontally or slightly inclined (with an inclination angle of 0 °~5 °). After the screening machine is started, the shaking body of the screening machine, that is, the screening box, moves back and forth under the action of inertia. The screening box drives the screening surface to shake periodically, so that the material on the screening surface moves in a directional jumping motion together with the screening box. During this process, the material smaller than the aperture of the screening surface falls to the lower layer through the screening hole, becoming the undersized material. The material larger than the aperture of the screening surface is discharged from the discharge port after continuous rolling and jumping motion, thus completing the screening work.

From the perspective of the motion trajectory of the shaking body or screening box of the screening machine, the square swinging screen, also known as the arc-shaped screen, generates an inertial force with a certain regularity in direction around a fixed axis due to the vibration force generated by its driving device. Its essence is the reciprocating inertial force formed by the rotation of the eccentric wheel around the fixed axis. According to the structural characteristics and working principle of the square oscillating vibrating screen, its screen surface is generally arranged horizontally or slightly inclined (with an inclination angle of 0 °~5 °). After the screening machine is started, the shaking body of the screening machine, that is, the screening box, moves back and forth under the action of inertia. The screening box drives the screening surface to shake periodically, so that the material on the screening surface moves in a directional jumping motion together with the screening box. During this process, the material smaller than the aperture of the screening surface falls to the lower layer through the screening hole, becoming the undersized material. The material larger than the aperture of the screening surface is discharged from the discharge port after continuous rolling and jumping motion, thus completing the screening work.

product structure

- The square swing screen is mainly composed of components such as feed inlet, screen box, drive device, screen frame, support frame, vibration reduction device, and discharge outlet.

Feed inlet: The original design attached to the rear door has been changed, and a material distribution plate structure has been added to make material distribution more effective and uniform The weight of the back door has been reduced, making the swinging motion at the feeding end more powerful, allowing the material to be quickly dispersed and screened on the screen surface.

Screening box: includes components such as screening frame, screen mesh, screening grid, spring card, and bouncing ball. The screening frame is equipped with upper and lower layers of screen mesh. The screen mesh is tensioned on the screen grid by spring cards set around the perimeter of the screen grid, and the bouncing ball is set in the grid of the screen grid.

Drive device: includes components such as driver, motor, locking sleeve, locking round nut, stop washer, and cone sleeve. The cone sleeve is fixed on the screen frame, and the drive shaft of the driver is set inside the cone sleeve and connected in place through the locking sleeve.

Universal shaft: The entire screening box is connected by a universal shaft. When the screening machine swings, the universal shaft also rotates, providing a buffering and damping effect on the rotational power, making the entire screening machine run more smoothly.

Discharge port: According to the customer's material screening needs, various designs are made based on different mesh layer requirements. Our design focuses more on facilitating large flow, fast and unobstructed outflow of the screen body, changing various angles, increasing the diameter of the discharge pipeline, reducing the outflow distance and other process methods

Product details

Product Parameters

model | effective area (m2) | power (Kw) | Screen inclination angle (°) | Rotation frequency (r/min) | layers | Screen box formation (mm) |

|---|---|---|---|---|---|---|

FYBS1030 | 3 | 3 | 5~8 | 180-260 | 1-5 | 25-60 |

FYBS1036 | 3.6 | 3 | ||||

FYBS1230 | 3.6 | 4 | ||||

FYBS1236 | 4.32 | 4 | ||||

FYBS1530 | 4.5 | 5.5 | ||||

FYBS1536 | 5.4 | 5.5 | ||||

FYBS1830 | 5.4 | 7.5 | ||||

FYBS1836 | 6.48 | 7.5 | ||||

FYBS2030 | 6 | 7.5 |

Application Scenarios: First Choice for Large-scale Production in Multiple Industries

- Food Industry: Grading and impurity removal of flour, starch and powdered sugar; size screening of nuts and grains.

- Pharmaceutical Industry: Precision grading of bulk drugs and traditional Chinese medicine granules to avoid cross-contamination.

- Chemical Industry: Filtration and grading of plastic particles, pigments and coatings.

- Mining Industry: Particle size screening of mineral powder and quartz sand to improve the purity of finished products.

Keywords:

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

FAQ

Product related questions

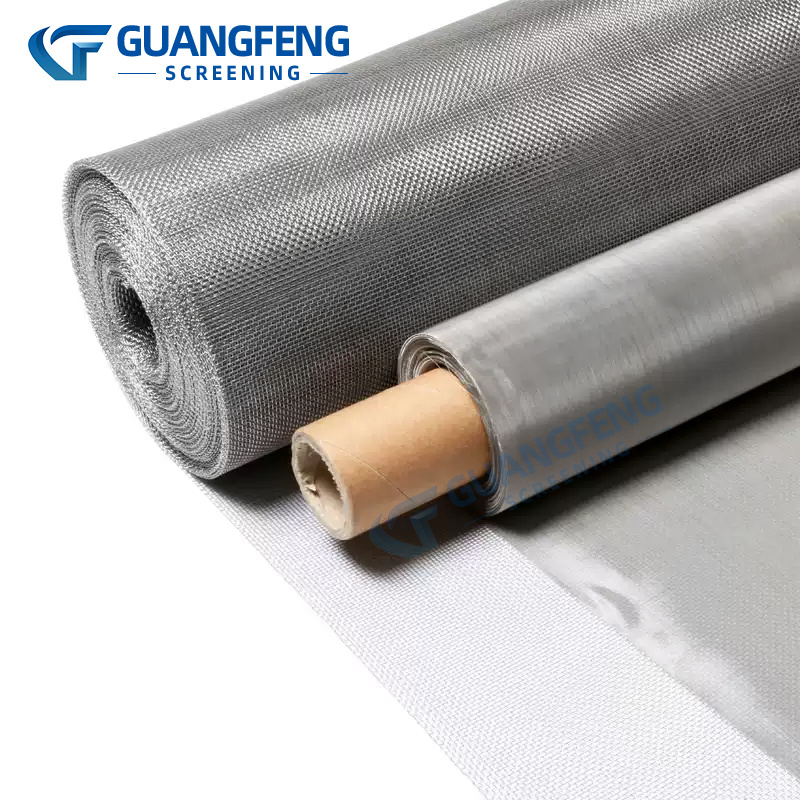

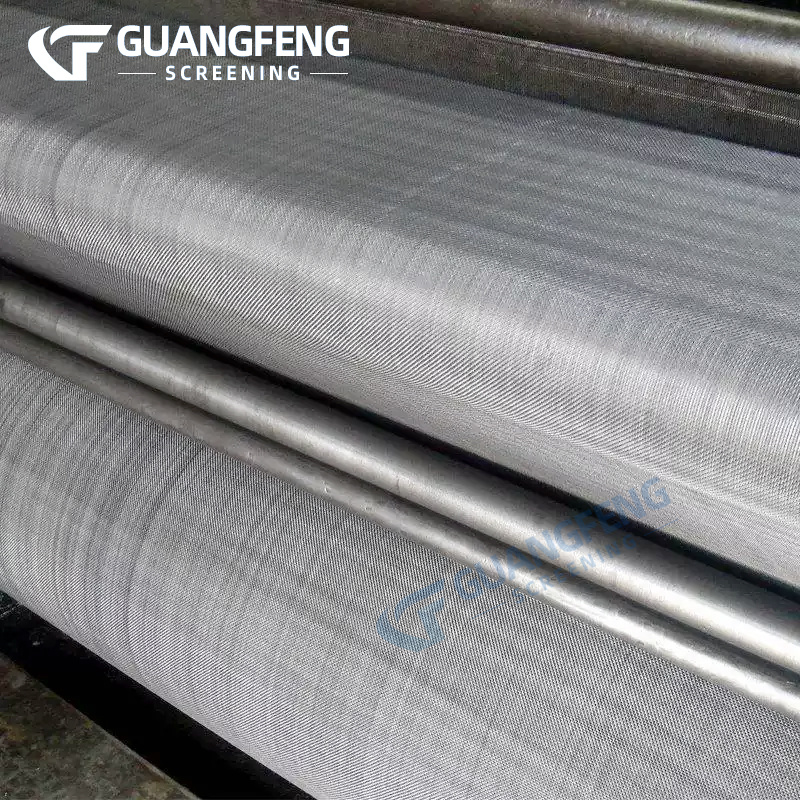

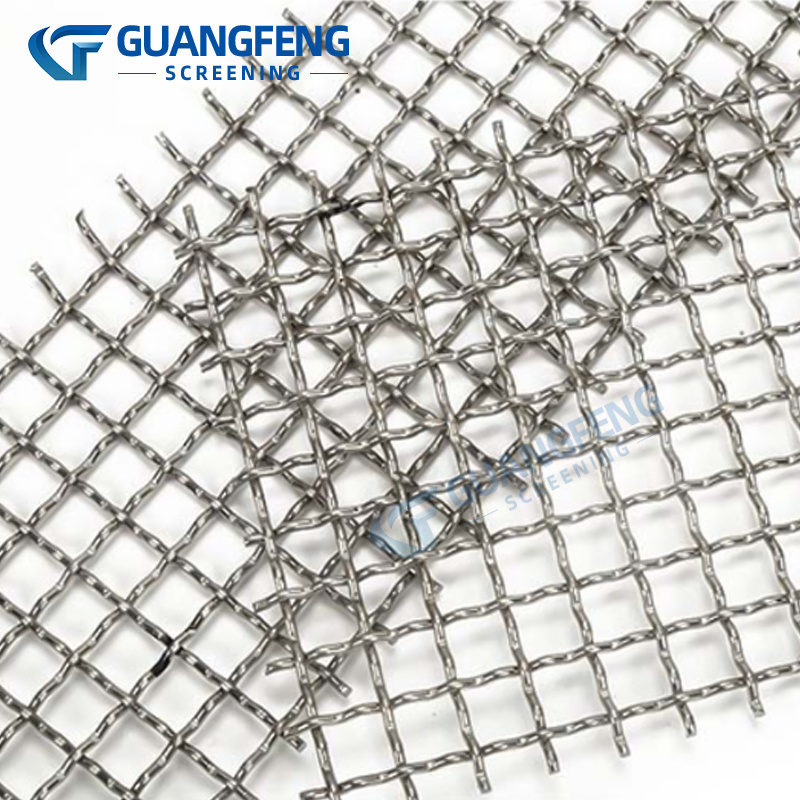

- Material:

Q “What kind of material is used in your stainless steel screen mesh?”

A “Our screen mesh is mainly made of high quality stainless steel, such as 304, 316L, which is rust-proof, corrosion-resistant, and can be adapted to different working environments.”

- Size:

Q “What are the specifications of screen mesh? Can it be customized?”

A “We have a variety of standard specifications, such as mesh size from 10 mesh to 500 mesh, width 0.5 meters to 2 meters, etc. We can also customize special specifications according to your needs. We can also customize special specifications according to your needs.”

- Product performance:

Q “What is the filtration precision of stainless steel screen mesh?”

A “The filtration precision depends on the mesh number, the higher the mesh number, the higher the precision. For example, 100 mesh screen can filter out particles larger than about 0.15mm.”

Production and processing issues

- Production cycle:

Q “How long will it take to ship after ordering?”

A “Conventional products will be shipped within 15-20 working days after receiving the payment, and customized products will take 20-30 working days, depending on the order quantity.”

- Processing technology:

Q “How are the screens produced?”

A “We adopt advanced weaving or welding technology, through drawing, weaving, cutting, welding, surface treatment and other processes to ensure product quality.”

Application and installation issues

- Application:

Q “What industries are stainless steel screen mesh applicable to?”

A “Widely used in mining, chemical, food, pharmaceutical, construction and other industries, such as mining ore screening, chemical liquid filtration.”

- Installation method:

Q “How to install the screen?”

A “Installation needs to be based on the use of the scene and equipment to choose the appropriate method. For example, if used in vibrating screen, the screen frame should be fixed first, and then the screen mesh should be tautly fixed with special fixture.”

After-sales and service issues

- After-sales service:

Q “How can I get help if I have problems in using it?”

A “You can contact our customer service team at any time, provide product information and problem description, we will provide timely solutions.”