PRODUCTS

CONTACT

Phone: +86-373-3765418

E-mail: service@gfscreening.com

Address: No.1, Jingyi Road, Youfang Dixiang, Guandi Township, High-tech Zone, Xinxiang City, Henan Province

Ultrasonic Vibrating Screen

- Commodity name: Ultrasonic Vibrating Screen

Ultrasonic vibrating screen is a high-precision screening equipment that can screen fine powders. It can be sieved up to 600 mesh. It is widely used in industries such as chemical, pharmaceutical, food, papermaking, metallurgy, building materials, rubber, and machinery. The screening effect is significant for powder particles with strong adsorption, easy agglomeration, high static electricity, and light density. The sieve has a long service life, a fully enclosed structure, no dust overflow, and is easy to operate and maintain.

Technical Features: Quality Reflected in Details

working principle

Ultrasonic vibrating screen converts 220V, 50HZ or 110V, 60Hz electrical energy into 38KHZ high-frequency electrical energy, which is input into an ultrasonic transducer to achieve efficient screening and net cleaning. This system introduces a low amplitude, high-frequency ultrasonic vibration wave (mechanical wave) on the basis of a traditional vibrating screen, and superimposes a high-frequency, low amplitude ultrasonic vibration instrument on the screen. The ultrafine powder receives huge ultrasonic acceleration, keeping the material on the screen surface in a suspended state, thereby suppressing factors such as adhesion, friction, leveling, etc. Solved the screening problems of strong adsorption, easy aggregation, high static electricity, high precision, high density, and light density, making ultrafine powder screening no longer difficult, especially suitable for users of high-quality and fine powders.

Ultrasonic vibrating screen converts 220V, 50HZ or 110V, 60Hz electrical energy into 38KHZ high-frequency electrical energy, which is input into an ultrasonic transducer to achieve efficient screening and net cleaning. This system introduces a low amplitude, high-frequency ultrasonic vibration wave (mechanical wave) on the basis of a traditional vibrating screen, and superimposes a high-frequency, low amplitude ultrasonic vibration instrument on the screen. The ultrafine powder receives huge ultrasonic acceleration, keeping the material on the screen surface in a suspended state, thereby suppressing factors such as adhesion, friction, leveling, etc. Solved the screening problems of strong adsorption, easy aggregation, high static electricity, high precision, high density, and light density, making ultrafine powder screening no longer difficult, especially suitable for users of high-quality and fine powders.

product structure

- The ultrasonic rotary vibrating screen is mainly composed of a base, vibration motor, screen mesh, screen frame, ultrasonic system, etc.

The base is located at the bottom, supporting and fixing the entire ultrasonic rotary vibrating screen body. The vibration motor is the main power source for mechanical operation, and the screen frame and mesh are the main contact tools for screening materials. The ultrasonic system consists of ultrasonic transducers, ultrasonic grids, and ultrasonic generators. The ultrasonic screening system is the key to upgrading the screening effect.

Product details

Product Parameters

model | Effective screening diameter(mm) | Effective screening area(m°) | Mesh specification | layers | Number of transducers | Motor power (Kw) |

|---|---|---|---|---|---|---|

GF-600 | Φ600 | 0.2826 | 2-500mesh | 1-2 | 1 | 0.25 |

GF-800 | Φ800 | 0.5024 | 1-2 | 1 | 0.25 | |

GF-1000 | Φ1000 | 0.785 | 1-2 | 1 | 0.75 | |

GF-1200 | Φ1200 | 1.1304 | 1-2 | 1 | 1.1 |

Application Scenarios: First Choice for Large-scale Production in Multiple Industries

Ultrasonic vibrating screen is suitable for screening high-precision, high static electricity, high-density, and lightweight materials.

- Food industry: flour, sugar, plant protein, milk powder, salt, five spice powder, pepper powder, Sichuan pepper powder, monosodium glutamate

- Chemical industry: plastic powder, rubber powder, pigments, fillers, resin powder, polytetrafluoroethylene powder

- Metallurgical industry: includes alloy powder, (gold, silver, copper, aluminum, nickel, chromium, magnesium, zinc, barium, vanadium, Qin, strontium, lead) powder, casting sand, etc

- Pharmaceutical industry: Western medicine powder, traditional Chinese medicine powder, pharmaceutical intermediates, pearl powder, etc.

Keywords:

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

FAQ

Product related questions

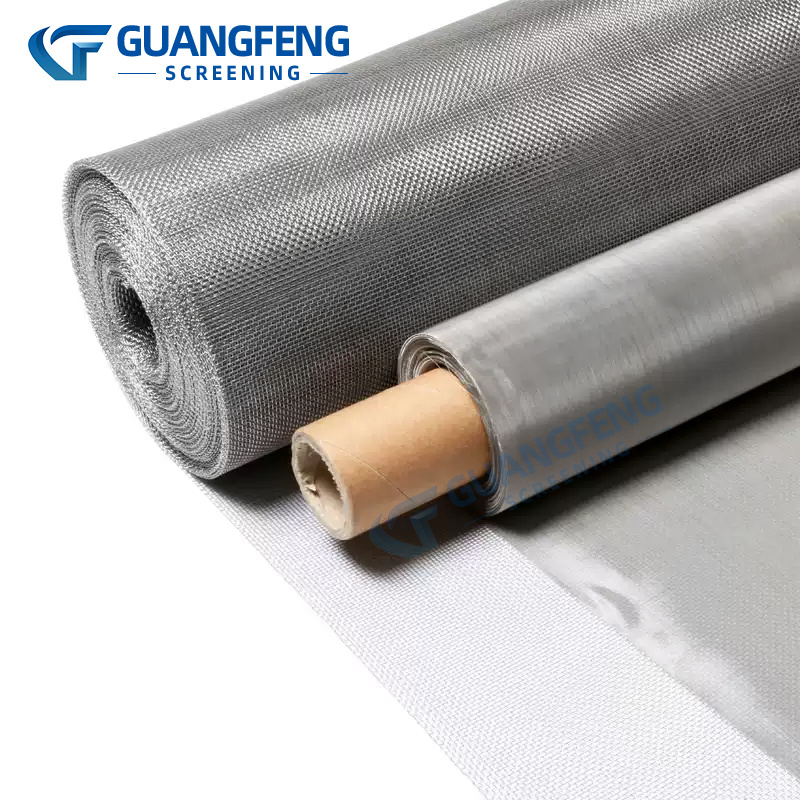

- Material:

Q “What kind of material is used in your stainless steel screen mesh?”

A “Our screen mesh is mainly made of high quality stainless steel, such as 304, 316L, which is rust-proof, corrosion-resistant, and can be adapted to different working environments.”

- Size:

Q “What are the specifications of screen mesh? Can it be customized?”

A “We have a variety of standard specifications, such as mesh size from 10 mesh to 500 mesh, width 0.5 meters to 2 meters, etc. We can also customize special specifications according to your needs. We can also customize special specifications according to your needs.”

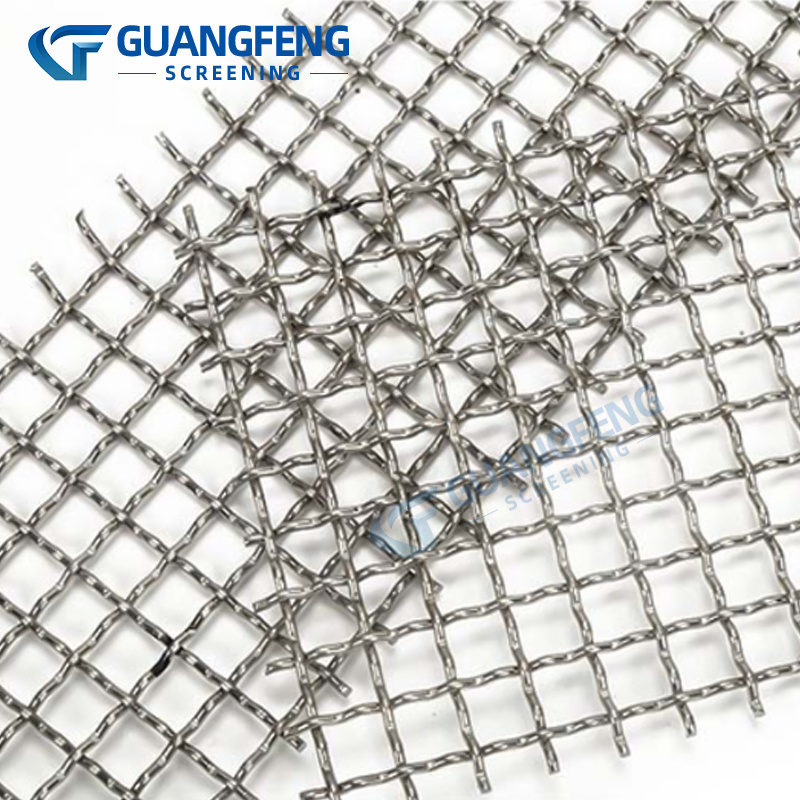

- Product performance:

Q “What is the filtration precision of stainless steel screen mesh?”

A “The filtration precision depends on the mesh number, the higher the mesh number, the higher the precision. For example, 100 mesh screen can filter out particles larger than about 0.15mm.”

Production and processing issues

- Production cycle:

Q “How long will it take to ship after ordering?”

A “Conventional products will be shipped within 15-20 working days after receiving the payment, and customized products will take 20-30 working days, depending on the order quantity.”

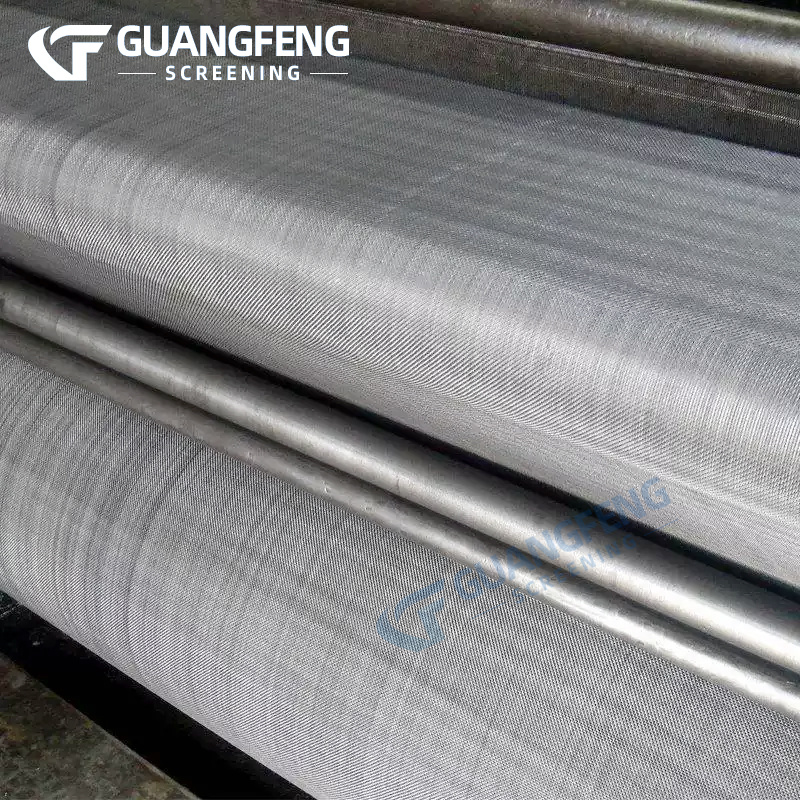

- Processing technology:

Q “How are the screens produced?”

A “We adopt advanced weaving or welding technology, through drawing, weaving, cutting, welding, surface treatment and other processes to ensure product quality.”

Application and installation issues

- Application:

Q “What industries are stainless steel screen mesh applicable to?”

A “Widely used in mining, chemical, food, pharmaceutical, construction and other industries, such as mining ore screening, chemical liquid filtration.”

- Installation method:

Q “How to install the screen?”

A “Installation needs to be based on the use of the scene and equipment to choose the appropriate method. For example, if used in vibrating screen, the screen frame should be fixed first, and then the screen mesh should be tautly fixed with special fixture.”

After-sales and service issues

- After-sales service:

Q “How can I get help if I have problems in using it?”

A “You can contact our customer service team at any time, provide product information and problem description, we will provide timely solutions.”