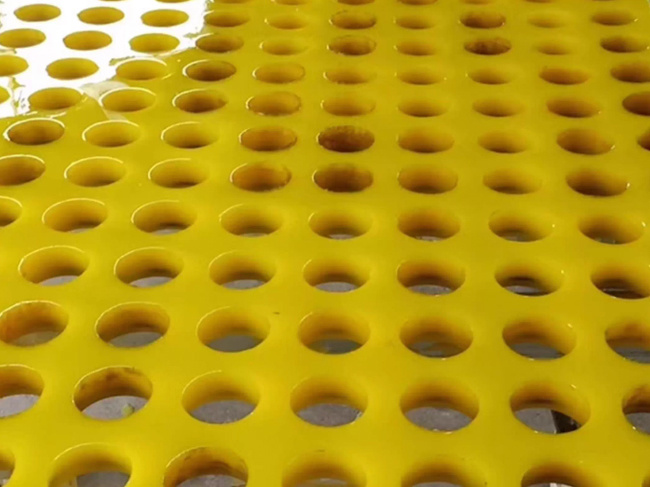

Product Name: Polyurethane Screen Mesh

Product Material: Polyurethane

Product specifications: Multiple styles to choose from

Product type: roll type, flat sheet type

Product specifications: road construction, stone processing, mining beneficiation, coal mine metallurgy, chemical industry, petroleum, construction.

PRODUCTS

CONTACT

Phone: +86-373-3765418

E-mail: service@gfscreening.com

Address: No.1, Jingyi Road, Youfang Dixiang, Guandi Township, High-tech Zone, Xinxiang City, Henan Province

Polyurethane Network

- Commodity name: Polyurethane Network

Product characteristics

High strength and wear resistance

High strength and wear resistance

Using steel wire rope as the skeleton material, polyurethane itself has high elastic modulus, high strength to absorb impact force, high tensile strength, and a bearing capacity that is more than 2.5 times that of rubber screen plates. Its wear resistance is excellent, and its service life is 8-10 times longer than that of ordinary metal screen plates, 3 times that of stainless steel screen plates, and 3.9 times that of natural rubber.

- High screening efficiency

The polyurethane mesh has a large cone angle (140 °), strong water permeability, and good self-cleaning performance. It can effectively prevent the adhesion of wet fine particles and avoid clogging under dynamic conditions. It is suitable for screening and grading wet fine particles with high screening efficiency.

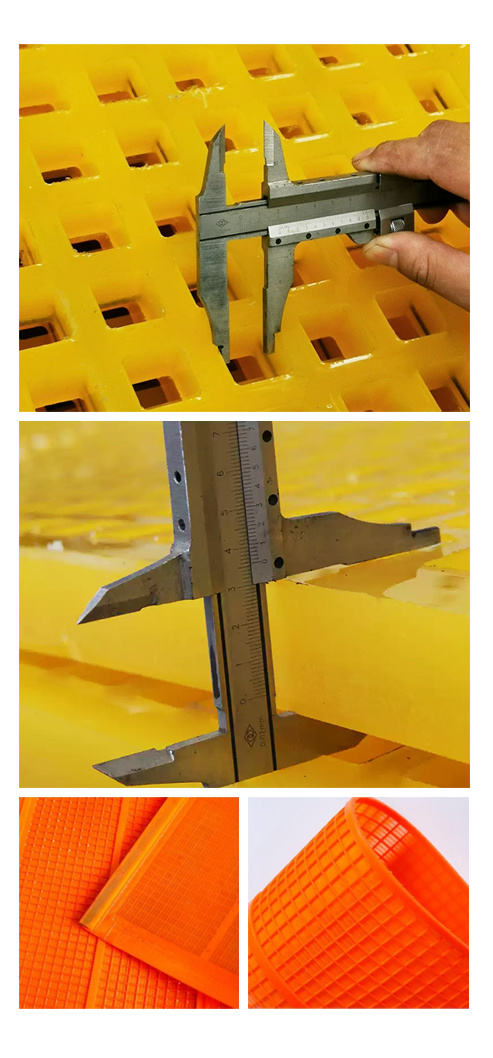

- High precision screening

Adopting the mold casting process, the aperture is accurate, the screening quality is high, and the particle size of the screened material can meet the user's requirements very well.

- Low noise and environmental protection

According to actual measurements, using polyurethane screen plates for the same screening machine can reduce noise by 5-20 decibels compared to metal screen plates, and greatly reduce dust flying, thus creating a peaceful and clean working environment on the production site.

- Energy Saving

Polyurethane has a low density (1.32kg/m ³) and is lighter in weight than metal screen surfaces, which can reduce production unit consumption, alleviate screen machine load, save electricity consumption, and extend screen machine life.

Product parameters

Product Details

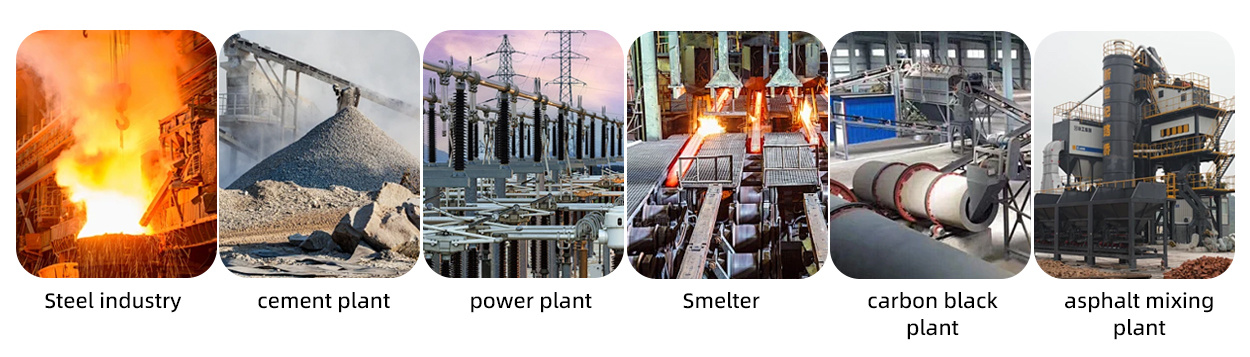

Application Industry

Mining: In the process of mining and beneficiation, it can effectively separate the required ore, improve mineral recovery rate, and is widely used in screening of iron ore, coal, and other minerals.

Architecture: It can effectively screen sand and gravel, ensure the particle uniformity of building materials, improve building quality, and is used for screening building aggregates and other materials.

Chemical industry: Its corrosion resistance makes it excellent in handling various chemical substances and can be used for fine screening of chemical raw materials.

Food industry: With its safe and non-toxic characteristics, it is applied in food production, such as screening of grains, seasonings, etc., to ensure product quality.

Keywords:

Get A Quote

We will contact you within one working day. Please pay attention to your email.

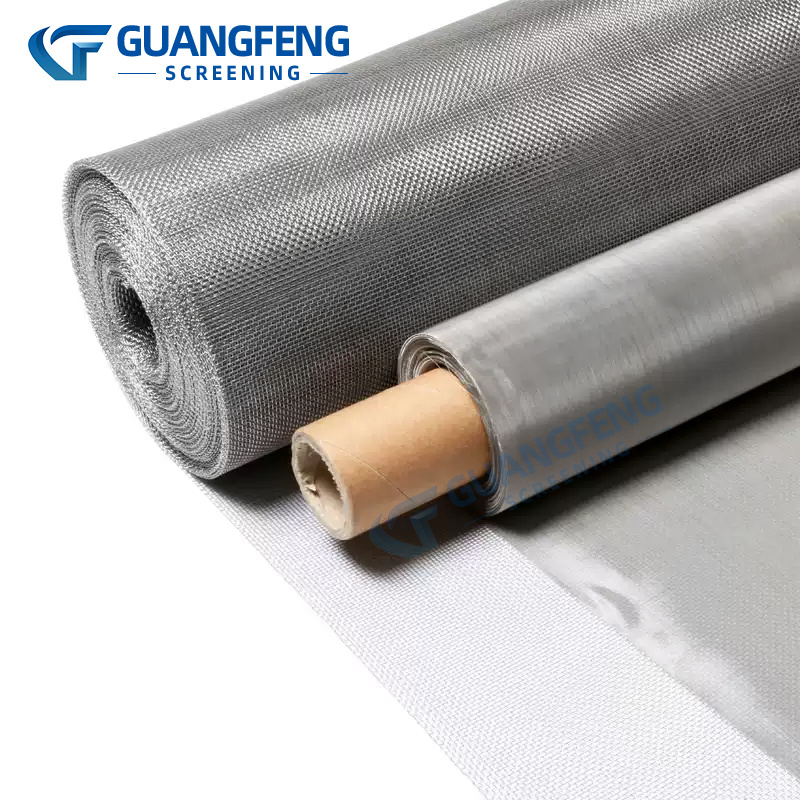

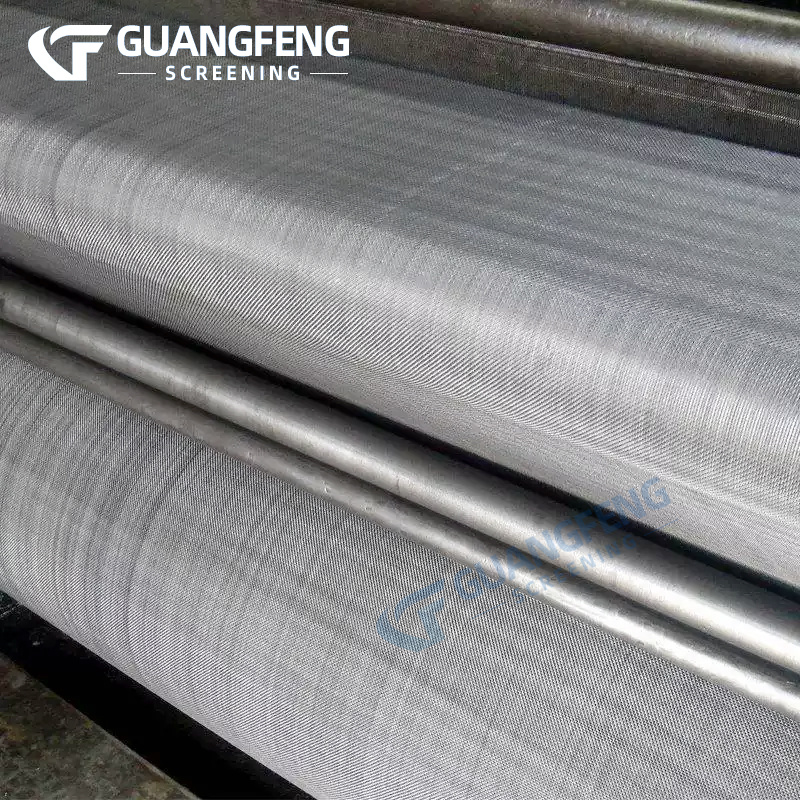

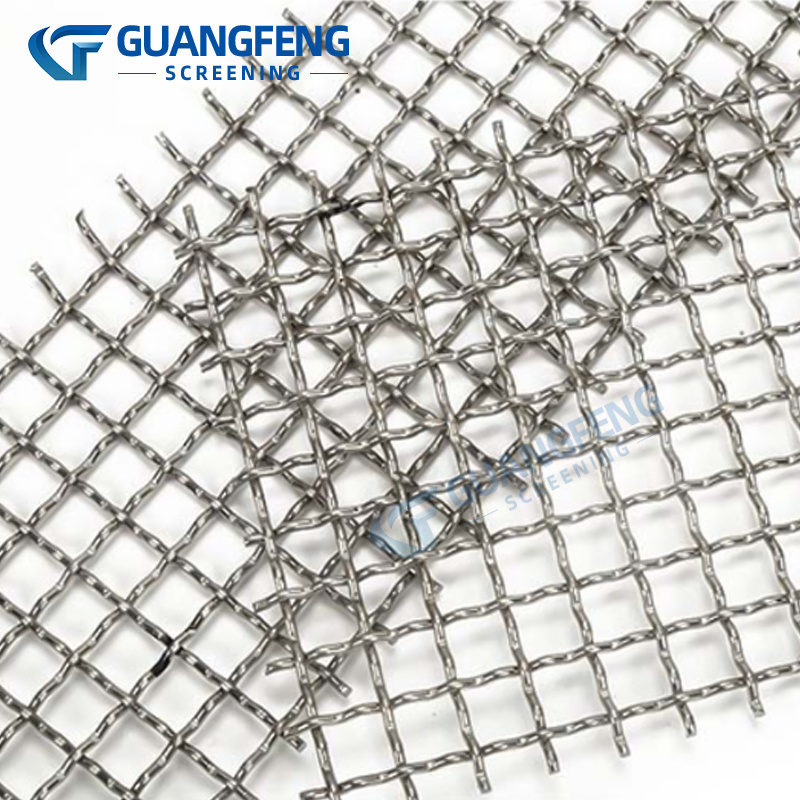

Related Products

FAQ

Product related questions

- Material:

Q “What kind of material is used in your stainless steel screen mesh?”

A “Our screen mesh is mainly made of high quality stainless steel, such as 304, 316L, which is rust-proof, corrosion-resistant, and can be adapted to different working environments.”

- Size:

Q “What are the specifications of screen mesh? Can it be customized?”

A “We have a variety of standard specifications, such as mesh size from 10 mesh to 500 mesh, width 0.5 meters to 2 meters, etc. We can also customize special specifications according to your needs. We can also customize special specifications according to your needs.”

- Product performance:

Q “What is the filtration precision of stainless steel screen mesh?”

A “The filtration precision depends on the mesh number, the higher the mesh number, the higher the precision. For example, 100 mesh screen can filter out particles larger than about 0.15mm.”

Production and processing issues

- Production cycle:

Q “How long will it take to ship after ordering?”

A “Conventional products will be shipped within 15-20 working days after receiving the payment, and customized products will take 20-30 working days, depending on the order quantity.”

- Processing technology:

Q “How are the screens produced?”

A “We adopt advanced weaving or welding technology, through drawing, weaving, cutting, welding, surface treatment and other processes to ensure product quality.”

Application and installation issues

- Application:

Q “What industries are stainless steel screen mesh applicable to?”

A “Widely used in mining, chemical, food, pharmaceutical, construction and other industries, such as mining ore screening, chemical liquid filtration.”

- Installation method:

Q “How to install the screen?”

A “Installation needs to be based on the use of the scene and equipment to choose the appropriate method. For example, if used in vibrating screen, the screen frame should be fixed first, and then the screen mesh should be tautly fixed with special fixture.”

After-sales and service issues

- After-sales service:

Q “How can I get help if I have problems in using it?”

A “You can contact our customer service team at any time, provide product information and problem description, we will provide timely solutions.”