PRODUCTS

CONTACT

Phone: +86-373-3765418

E-mail: service@gfscreening.com

Address: No.1, Jingyi Road, Youfang Dixiang, Guandi Township, High-tech Zone, Xinxiang City, Henan Province

Linear vibrating screen

- Commodity name: Linear vibrating screen

The linear vibrating screen is mainly composed of a screen box, screen frame, screen mesh, vibration motor, motor pedestal, damping spring, bracket, etc. The linear vibrating screen uses a vibration motor to excite as a vibration source, causing the material to be thrown up on the screen while moving forward in a straight line. The material is evenly fed from the feeder into the feed inlet of the screening machine, and through multiple layers of screens, several specifications of sieved material and undersized material are produced and discharged from their respective outlets. It has the characteristics of low energy consumption, high output, simple structure, easy maintenance, fully enclosed structure, no dust overflow, automatic discharge, and is more suitable for assembly line operations

Technical Features: Quality Reflected in Details

working principle

1. Vibration motor drive: The operation of the linear sieve is driven by a vibration motor. The vibration motor generates excitation force through the exciter, and moves the sieve box in a straight line.

1. Vibration motor drive: The operation of the linear sieve is driven by a vibration motor. The vibration motor generates excitation force through the exciter, and moves the sieve box in a straight line.

2. Material input: The materials to be screened are fed into the screening box through the feeding port.

3. Screening process: The materials inside the screening box are subjected to centrifugal and inertial forces under the action of vibration, and move in a straight line on the screening screen. Smaller particles will pass through the pores of the sieve, while larger particles will be blocked on the surface of the sieve.

4. Material separation: During the screening process, materials that meet the requirements will fall into the aggregate box or conveyor belt below through the sieve, while materials that do not meet the requirements will be retained on the sieve.

5. Adjust vibration parameters: By adjusting the amplitude and frequency of the vibration motor, the screening speed and screening effect of the material can be controlled to meet the screening requirements of different materials.

product structure

- The linear screen is mainly composed of a screen box, screen frame, screen mesh, vibration motor, motor pedestal, vibration reducing spring, bracket, etc.

Screening box: made of welded steel plates of different thicknesses, with certain strength and rigidity, it is the main component of the screening machine;

Screen frame: available in stainless steel, carbon steel, or wood materials, mainly used to maintain the flatness of the screen mesh and achieve normal screening;

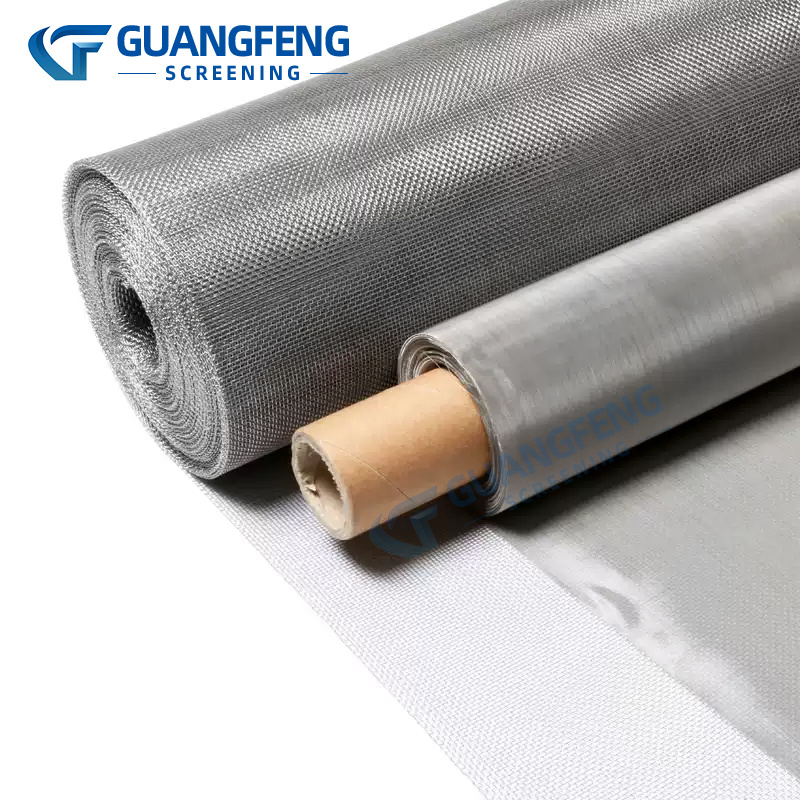

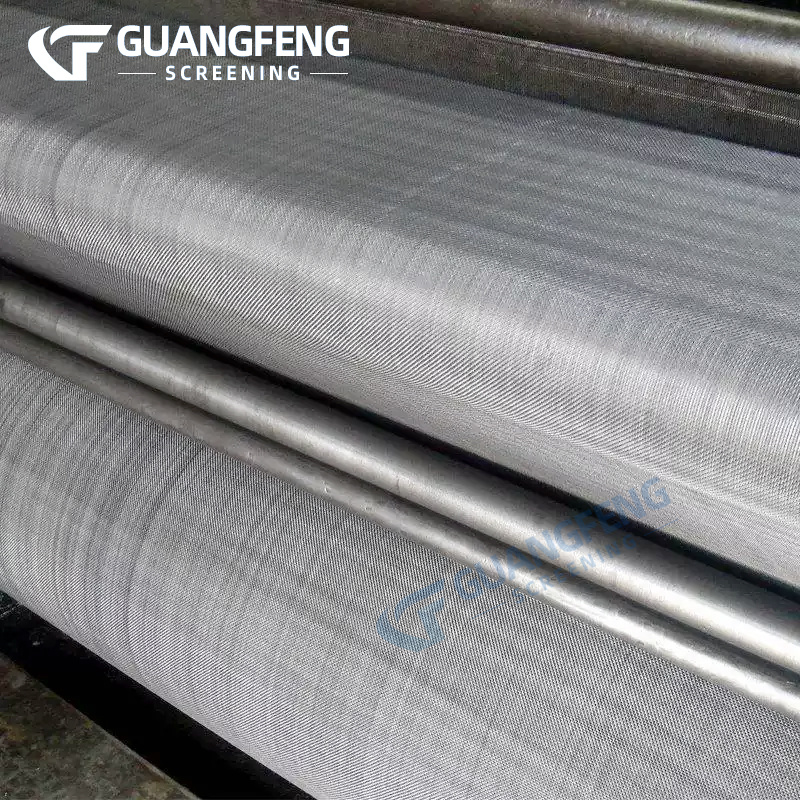

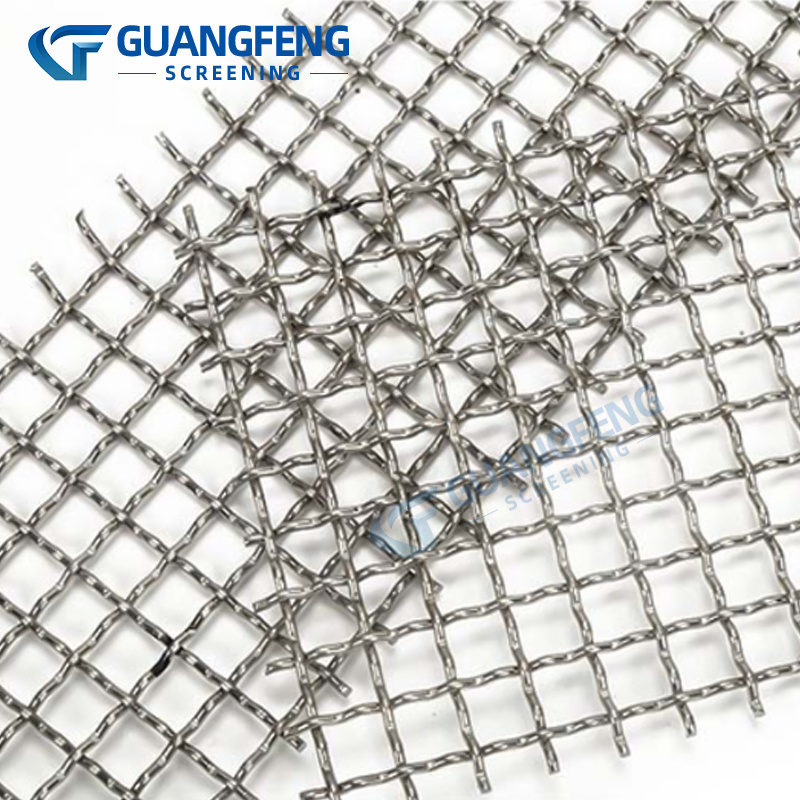

Screen mesh: There are several types of screens including low-carbon steel, brass, bronze, stainless steel wire, etc;

Motor pedestal: When installing the vibration motor, the connecting screws must be tightened before use, especially three days before the trial use of the new screening machine, which must be repeatedly tightened to avoid loosening and causing accidents;

Vibration damping spring: prevents vibration from being transmitted to the ground while supporting the entire weight of the screen box. During installation, the spring must be perpendicular to the ground;

Bracket: Composed of four pillars and two channel steels, it supports the sieve box. During installation, the pillars must be perpendicular to the ground, and the channel steels under the two pillars should be parallel to each other.

Product details

Product Parameters

model | nominal size(mm) | Material particle size(mm) | Screen inclination angle | amplitude(mm) | layers | power(Kw) |

|---|---|---|---|---|---|---|

GF-520 | 500x2000 | 0.074-10 | 1° -7° | 3-4.5 | 1-6 | 2x(0.4-0.75) |

GF-525 | 500x2500 | 0.074-10 | 2x(0.4-0.75) | |||

GF-1020 | 500x2000 | 0.074-10 | 2x(0.4-0.75) | |||

GF-1025 | 500x2500 | 0.074-10 | 2x(0.4-1.1) |

Application Scenarios: First Choice for Large-scale Production in Multiple Industries

- Mining and metallurgical industry: used for screening and grading raw materials such as ores, coal, metallic ores, non-metallic ores, etc., such as screening ores in mineral processing plants to separate ores of different particle sizes to meet the needs of smelting and processing.

- Chemical industry: used for screening and grading of chemical raw materials and granular materials, such as screening raw materials in the production process of granular materials to ensure product quality.

- Food industry: used for screening and grading of food raw materials and food additives, such as screening powdered raw materials during food processing to remove impurities and improve product quality.

- Pharmaceutical and biotechnology industry: used for screening and grading of pharmaceutical raw materials and biological products, such as screening medicinal materials in pharmaceutical factories to separate them into qualified medicinal materials.

- Environmental Protection and Waste Management Industry: Used in environmental protection fields such as waste treatment and recycling, such as screening waste in garbage treatment plants to separate recyclable materials.

- Other industries: It can also be applied to screening work in the production process of ceramics, glass, plastics, papermaking, wood processing and other industries.

Keywords:

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

FAQ

Product related questions

- Material:

Q “What kind of material is used in your stainless steel screen mesh?”

A “Our screen mesh is mainly made of high quality stainless steel, such as 304, 316L, which is rust-proof, corrosion-resistant, and can be adapted to different working environments.”

- Size:

Q “What are the specifications of screen mesh? Can it be customized?”

A “We have a variety of standard specifications, such as mesh size from 10 mesh to 500 mesh, width 0.5 meters to 2 meters, etc. We can also customize special specifications according to your needs. We can also customize special specifications according to your needs.”

- Product performance:

Q “What is the filtration precision of stainless steel screen mesh?”

A “The filtration precision depends on the mesh number, the higher the mesh number, the higher the precision. For example, 100 mesh screen can filter out particles larger than about 0.15mm.”

Production and processing issues

- Production cycle:

Q “How long will it take to ship after ordering?”

A “Conventional products will be shipped within 15-20 working days after receiving the payment, and customized products will take 20-30 working days, depending on the order quantity.”

- Processing technology:

Q “How are the screens produced?”

A “We adopt advanced weaving or welding technology, through drawing, weaving, cutting, welding, surface treatment and other processes to ensure product quality.”

Application and installation issues

- Application:

Q “What industries are stainless steel screen mesh applicable to?”

A “Widely used in mining, chemical, food, pharmaceutical, construction and other industries, such as mining ore screening, chemical liquid filtration.”

- Installation method:

Q “How to install the screen?”

A “Installation needs to be based on the use of the scene and equipment to choose the appropriate method. For example, if used in vibrating screen, the screen frame should be fixed first, and then the screen mesh should be tautly fixed with special fixture.”

After-sales and service issues

- After-sales service:

Q “How can I get help if I have problems in using it?”

A “You can contact our customer service team at any time, provide product information and problem description, we will provide timely solutions.”