PRODUCTS

CONTACT

Phone: +86-373-3765418

E-mail: service@gfscreening.com

Address: No.1, Jingyi Road, Youfang Dixiang, Guandi Township, High-tech Zone, Xinxiang City, Henan Province

Flat rotary screen

- Commodity name: Flat rotary screen

Flat rotary screen, also known as flat rotary screen or flat swing screen, has the advantages of reasonable design, simple structure, smooth operation, fully enclosed structure, dust-free, anti blocking hole, anti sticking mesh, etc. Especially for urea screening with strong moisture absorption, high viscosity, easy blockage of pores, and sticking to the mesh, it is more obvious. Due to the use of the principle of planar rotational motion, the dynamic to static ratio and foundation dynamic load of the equipment have been effectively reduced. This device uses a flat rotary vibrating screen to vibrate up and down, and there is an automatic cleaning device under the net. Compared with traditional linear screens, it improves the service life of the wire mesh, reduces noise, and has a large screening area. The efficiency has been increased from the original 93-95 to 99, and the promotion prospects are good.

Technical Features: Quality Reflected in Details

working principle

After the screening machine is started, the shaking body of the screening machine, that is, the screening box, moves back and forth under the action of inertia. The screening box drives the screening surface to shake periodically, so that the material on the screening surface moves in a directional jumping motion together with the screening box. During this process, the material smaller than the aperture of the screening surface falls to the lower layer through the screening hole, becoming the undersized material. The material larger than the aperture of the screening surface is discharged from the discharge port after continuous rolling and jumping motion, and finally completes the screening work.

After the screening machine is started, the shaking body of the screening machine, that is, the screening box, moves back and forth under the action of inertia. The screening box drives the screening surface to shake periodically, so that the material on the screening surface moves in a directional jumping motion together with the screening box. During this process, the material smaller than the aperture of the screening surface falls to the lower layer through the screening hole, becoming the undersized material. The material larger than the aperture of the screening surface is discharged from the discharge port after continuous rolling and jumping motion, and finally completes the screening work.

product structure

1. Screening box component: The screening box is the core component that carries material screening, directly determining screening efficiency and accuracy.

2. Drive system: The drive system provides a composite motion power of "flat rotation+slight up and down vibration" for the sieve box, which is the core of equipment operation.

3. Support device: The support device is used to fix the sieve box and reduce the transmission of vibration to the ground or frame, ensuring the smooth operation of the equipment.

4. Auxiliary system: The auxiliary system mainly enhances the practicality, safety, and environmental friendliness of the equipment.

Product details

Product Parameters

model | Screen surface area (m2) | layer | Feed particle size(mm) | amplitude(mm) | Rotational speed(r/min) | Motor model | power(Kw) |

|---|---|---|---|---|---|---|---|

GF-1224 | 1200x2400 | 1~2 | ≤15 | 40 | 1450 | Y132S-6 | 3 |

GF-1236 | 1236x3600 | ||||||

GF-1524 | 1500x2400 | ||||||

GF-1536 | 1500x3600 | 750 | |||||

GF-1836 | 1800x3600 | Y160L-6 | 11 | ||||

GF-2040 | 2000x4000 |

Application Scenarios

- Food industry: sugar powder, starch, salt, Rice noodles, milk powder, soybean milk, egg powder, soy sauce, fruit juice, etc.

- Pharmaceutical industry: industrial drugs, traditional Chinese medicine powders, granular pills, micro pills, etc.

- Chemical industry: resins, coatings, industrial drugs, cosmetics, etc.

- Metallurgical mining: aluminum powder, lead powder, copper powder, ore, alloy powder, welding rod powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, refractory materials, kaolin, lime, alumina, heavy calcium carbonate, quartz sand, etc.

Keywords:

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

FAQ

Product related questions

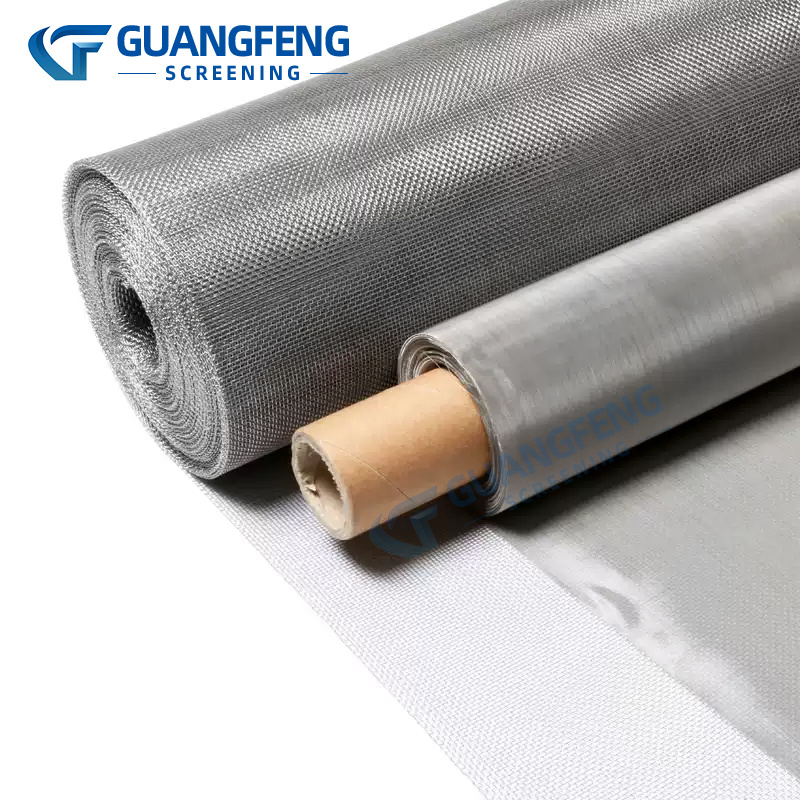

- Material:

Q “What kind of material is used in your stainless steel screen mesh?”

A “Our screen mesh is mainly made of high quality stainless steel, such as 304, 316L, which is rust-proof, corrosion-resistant, and can be adapted to different working environments.”

- Size:

Q “What are the specifications of screen mesh? Can it be customized?”

A “We have a variety of standard specifications, such as mesh size from 10 mesh to 500 mesh, width 0.5 meters to 2 meters, etc. We can also customize special specifications according to your needs. We can also customize special specifications according to your needs.”

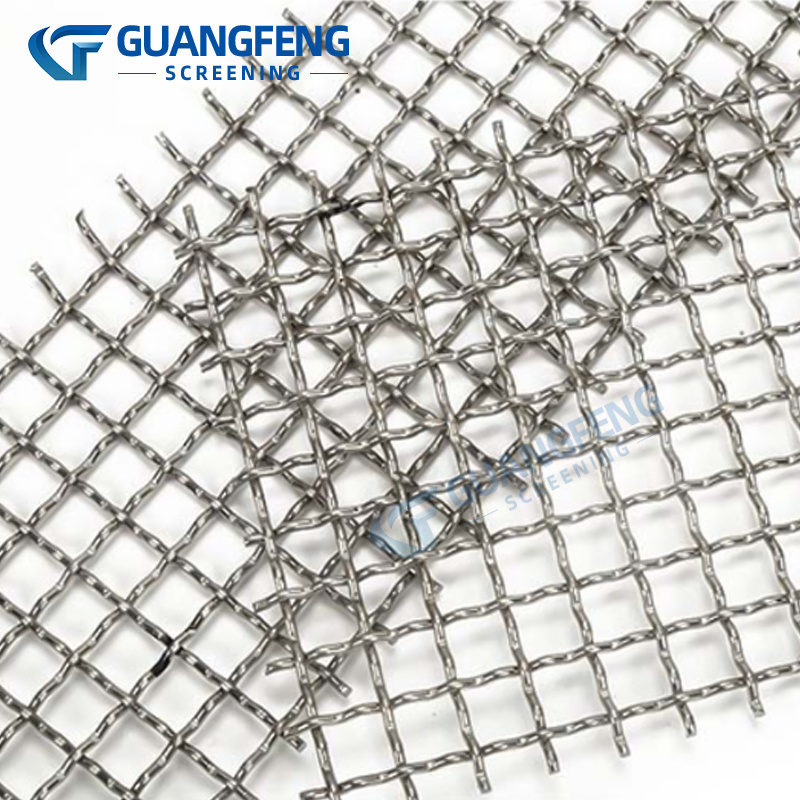

- Product performance:

Q “What is the filtration precision of stainless steel screen mesh?”

A “The filtration precision depends on the mesh number, the higher the mesh number, the higher the precision. For example, 100 mesh screen can filter out particles larger than about 0.15mm.”

Production and processing issues

- Production cycle:

Q “How long will it take to ship after ordering?”

A “Conventional products will be shipped within 15-20 working days after receiving the payment, and customized products will take 20-30 working days, depending on the order quantity.”

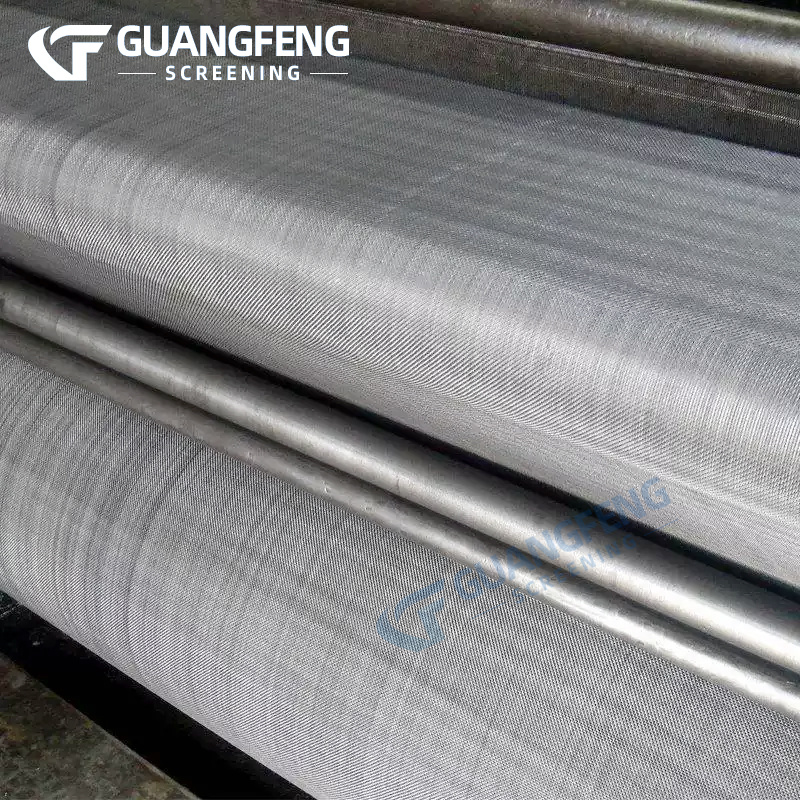

- Processing technology:

Q “How are the screens produced?”

A “We adopt advanced weaving or welding technology, through drawing, weaving, cutting, welding, surface treatment and other processes to ensure product quality.”

Application and installation issues

- Application:

Q “What industries are stainless steel screen mesh applicable to?”

A “Widely used in mining, chemical, food, pharmaceutical, construction and other industries, such as mining ore screening, chemical liquid filtration.”

- Installation method:

Q “How to install the screen?”

A “Installation needs to be based on the use of the scene and equipment to choose the appropriate method. For example, if used in vibrating screen, the screen frame should be fixed first, and then the screen mesh should be tautly fixed with special fixture.”

After-sales and service issues

- After-sales service:

Q “How can I get help if I have problems in using it?”

A “You can contact our customer service team at any time, provide product information and problem description, we will provide timely solutions.”