PRODUCTS

CONTACT

Phone: +86-373-3765418

E-mail: service@gfscreening.com

Address: No.1, Jingyi Road, Youfang Dixiang, Guandi Township, High-tech Zone, Xinxiang City, Henan Province

Dierct Discharge Vibrating Screen

- Commodity name: Dierct Discharge Vibrating Screen

Vertical vibrating screen is a vibrating screening equipment with small footprint and large processing capacity. It is widely used for rough screening of granular powders in industries such as food, metal, non-metal, chemical, and non mineral. It has a large processing capacity and is easy to combine with production lines. It can choose to use dual vibration motors or single vibration motors according to the processing capacity, and the material's running trajectory can be adjusted in various forms, significantly increasing the adaptability of the equipment; Due to the vertical discharge of materials, there is a larger processing capacity, and the discharge port is designed at the bottom of the screening machine, which is beneficial for improving the discharge speed and amount.

Technical Features: Quality Reflected in Details

working principle

The straight row vibrating screen uses a vibration motor as the excitation source. The vibration motor utilizes two sets of eccentric blocks (unbalanced eccentric blocks) at the upper and lower ends of its shaft to transform the rotational motion of the vibration motor into multiple overlapping forces of horizontal, vertical, inclined, and centrifugal effects. These forces are then transmitted to the screen surface to achieve the purpose of screening. Changing the phase angle and weight of the upper and lower eccentric blocks can alter the magnitude of the excitation force and the trajectory of the material's movement.

The straight row vibrating screen uses a vibration motor as the excitation source. The vibration motor utilizes two sets of eccentric blocks (unbalanced eccentric blocks) at the upper and lower ends of its shaft to transform the rotational motion of the vibration motor into multiple overlapping forces of horizontal, vertical, inclined, and centrifugal effects. These forces are then transmitted to the screen surface to achieve the purpose of screening. Changing the phase angle and weight of the upper and lower eccentric blocks can alter the magnitude of the excitation force and the trajectory of the material's movement.

product structure

The direct discharge screen is mainly composed of a vibration motor, screen body, screen cover, base, etc. The straight screening body consists of an upper screening body, an intermediate screening body, a screen mesh (screen body and mesh), a lower screening body, and connecting accessories. The intermediate screening body removes impurities after screening. Due to the different number of suspension motors, their names vary. A direct discharge screen with a motor suspended on the side of the screening machine, also known as a single vibration source direct discharge screen, and a direct discharge screen with two motors suspended on both sides of the screening machine, also known as a dual vibration source direct discharge screen.

Product details

Product Parameters

model | Motor power(Kw) | Motor speed(r/min) | Screen diameter(mm) | Overall dimensions(mm) |

|---|---|---|---|---|

ZPS-600 | 0.18 | 1450 | Φ580 | 1000x600x550 |

ZPS-800 | 0.25 | Φ780 | 1100x800x600 | |

ZPS-1000 | 0.55 | Φ960 | 1280x1000x700 | |

ZPS-1200 | 0.75 | Φ1160 | 1550x1200x750 | |

ZPS-1500 | 1.5 | Φ1460 | 1850x1500x900 |

Application Scenarios

- Food industry: sugar powder, starch, salt, Rice noodles, milk powder, soybean milk, egg powder, soy sauce, fruit juice, etc.

- Pharmaceutical industry: industrial drugs, traditional Chinese medicine powders, granular pills, micro pills, etc.

- Chemical industry: resins, coatings, industrial drugs, cosmetics, etc.

- Metallurgical mining: aluminum powder, lead powder, copper powder, ore, alloy powder, welding rod powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, refractory materials, kaolin, lime, alumina, heavy calcium carbonate, quartz sand, etc.

Keywords:

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

FAQ

Product related questions

- Material:

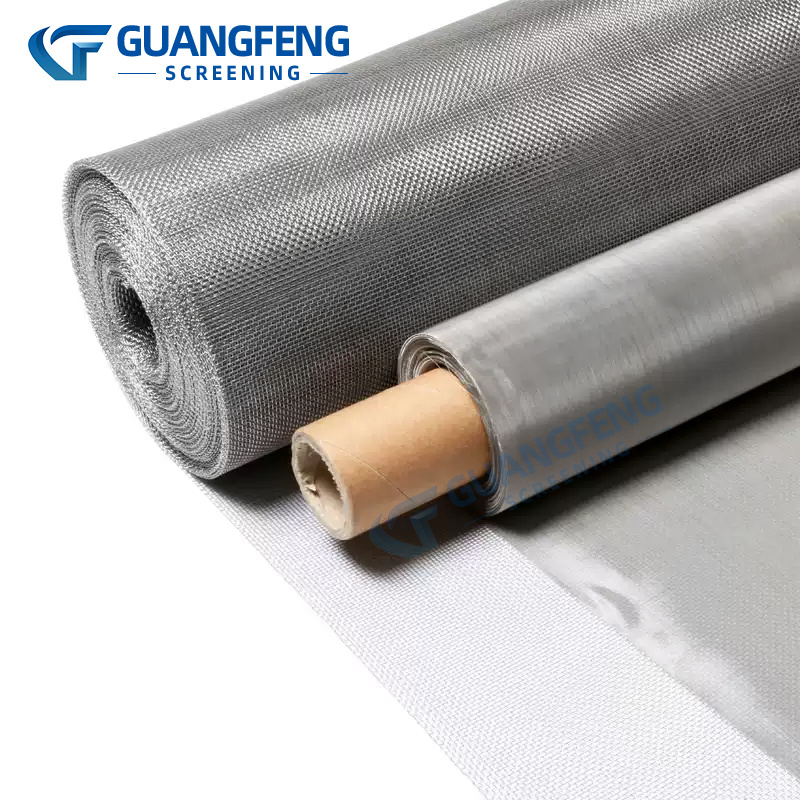

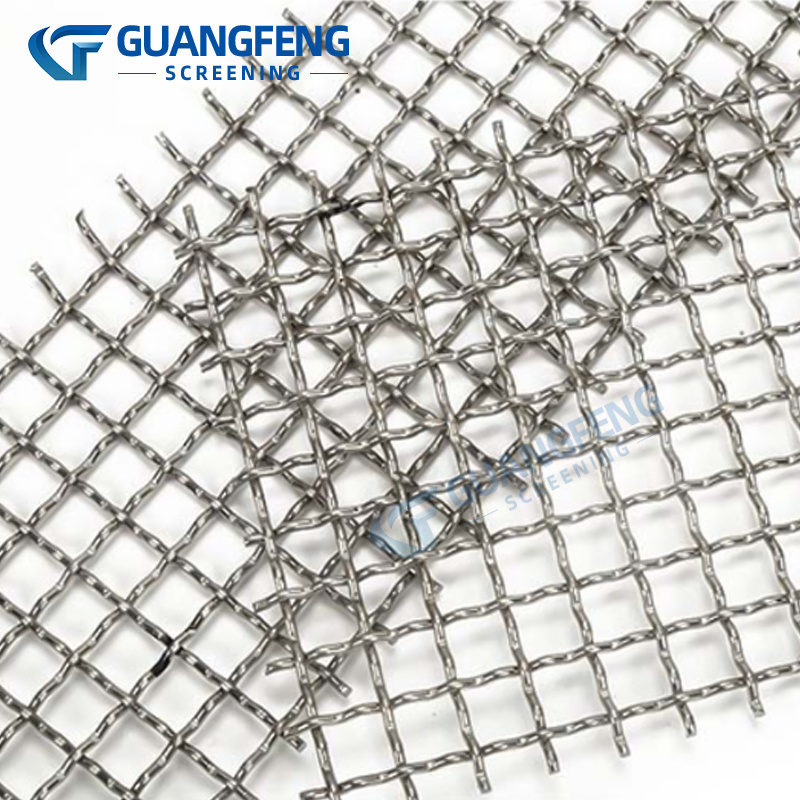

Q “What kind of material is used in your stainless steel screen mesh?”

A “Our screen mesh is mainly made of high quality stainless steel, such as 304, 316L, which is rust-proof, corrosion-resistant, and can be adapted to different working environments.”

- Size:

Q “What are the specifications of screen mesh? Can it be customized?”

A “We have a variety of standard specifications, such as mesh size from 10 mesh to 500 mesh, width 0.5 meters to 2 meters, etc. We can also customize special specifications according to your needs. We can also customize special specifications according to your needs.”

- Product performance:

Q “What is the filtration precision of stainless steel screen mesh?”

A “The filtration precision depends on the mesh number, the higher the mesh number, the higher the precision. For example, 100 mesh screen can filter out particles larger than about 0.15mm.”

Production and processing issues

- Production cycle:

Q “How long will it take to ship after ordering?”

A “Conventional products will be shipped within 15-20 working days after receiving the payment, and customized products will take 20-30 working days, depending on the order quantity.”

- Processing technology:

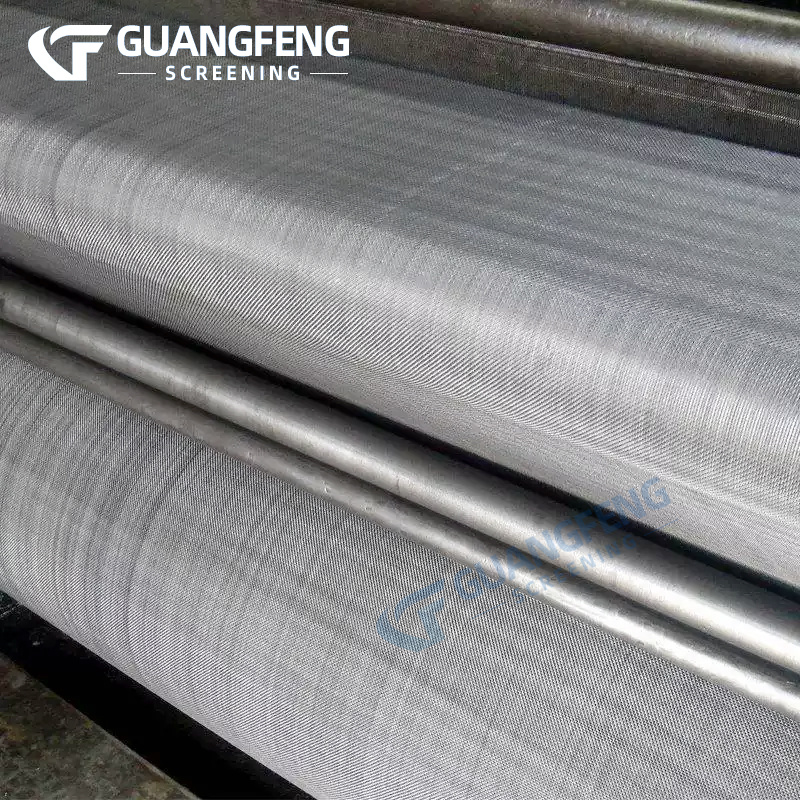

Q “How are the screens produced?”

A “We adopt advanced weaving or welding technology, through drawing, weaving, cutting, welding, surface treatment and other processes to ensure product quality.”

Application and installation issues

- Application:

Q “What industries are stainless steel screen mesh applicable to?”

A “Widely used in mining, chemical, food, pharmaceutical, construction and other industries, such as mining ore screening, chemical liquid filtration.”

- Installation method:

Q “How to install the screen?”

A “Installation needs to be based on the use of the scene and equipment to choose the appropriate method. For example, if used in vibrating screen, the screen frame should be fixed first, and then the screen mesh should be tautly fixed with special fixture.”

After-sales and service issues

- After-sales service:

Q “How can I get help if I have problems in using it?”

A “You can contact our customer service team at any time, provide product information and problem description, we will provide timely solutions.”