PRODUCTS

CONTACT

Phone: +86-373-3765418

E-mail: service@gfscreening.com

Address: No.1, Jingyi Road, Youfang Dixiang, Guandi Township, High-tech Zone, Xinxiang City, Henan Province

CircularSwinging screen

- Commodity name: CircularSwinging screen

Core Advantages: Precise Sieving, High Efficiency & Stability

Guangfeng Sieving's Swing Screen is designed around the core principle of simulating manual swinging motion. It combines high-frequency vibration with multi-dimensional swinging movement to achieve precise layering and efficient separation of materials on the screen surface. Compared with traditional sieving equipment, its unique "3D elliptical motion trajectory" significantly reduces material clogging, improves sieving accuracy and processing capacity. It is widely suitable for grading, impurity removal, filtration and other process requirements of powder and granular materials.

Technical Features: Quality Reflected in Details

Application Scenarios: Trusted in Multiple Fields

1. The basic rotational motion is similar to that of an artificial sieve. The eccentricity can be adjusted from 25 to 40mm, and the low-speed V-belt drive can be adjusted from 120 to 360rpm;

1. The basic rotational motion is similar to that of an artificial sieve. The eccentricity can be adjusted from 25 to 40mm, and the low-speed V-belt drive can be adjusted from 120 to 360rpm;

2. The residence time of each product can be adjusted by the radial and tangential directions of the swing screen towards the driving axis.

3. Therefore, establish horizontal and throwing three-dimensional rolling motion. The material is uniformly dispersed on the entire screening surface from the center to the outer edge, and then spreads in a spiral motion towards the axial direction, completing the entire screening process with fine particles;

4. The horizontal and vertical accelerations increase with the movement of particles, and particles close to the sieve size are successfully separated. Larger particles are transported to the outlet, where the flow rate is controlled by an adjustable guide device, which is the key to controlling the residence time of the material. This process is repeated between each sieve layer.

Detail Display

Product Parameters

model | effective area (m2) | Effective diameter (mm inch) | Screening layers | Motor power | Cleaning system | Reference weight (kg) |

|---|---|---|---|---|---|---|

YBS-600 | 0.2124 | 600 | 5th floor | 0.25/4 | Optional rubber ball, rotary brush, compressed air, ultrasonic, scraper | 410 |

YBS-1000 | 0.77 | 1040 | 1.5/4 | 400 | ||

YBS-1200 | 1.13 | 1250 | 2.2/4 | 480 | ||

YBS-1600 | 1.83 | 1580 | 3/4 | 890 | ||

YBS-2000 | 2 .63 | 1884 | 4/4 | 990 | ||

YBS-2600 | 5.3 | 2650 | 5.5/4 | 1660 |

Application Scenarios: Trusted in Multiple Fields

- Food Industry: Grading and impurity removal of flour, starch and powdered sugar; size screening of nuts and grains.

- Pharmaceutical Industry: Precision grading of bulk drugs and traditional Chinese medicine granules to avoid cross-contamination.

- Chemical Industry: Filtration and grading of plastic particles, pigments and coatings.

- Mining Industry: Particle size screening of mineral powder and quartz sand to improve the purity of finished products.

Keywords:

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

FAQ

Product related questions

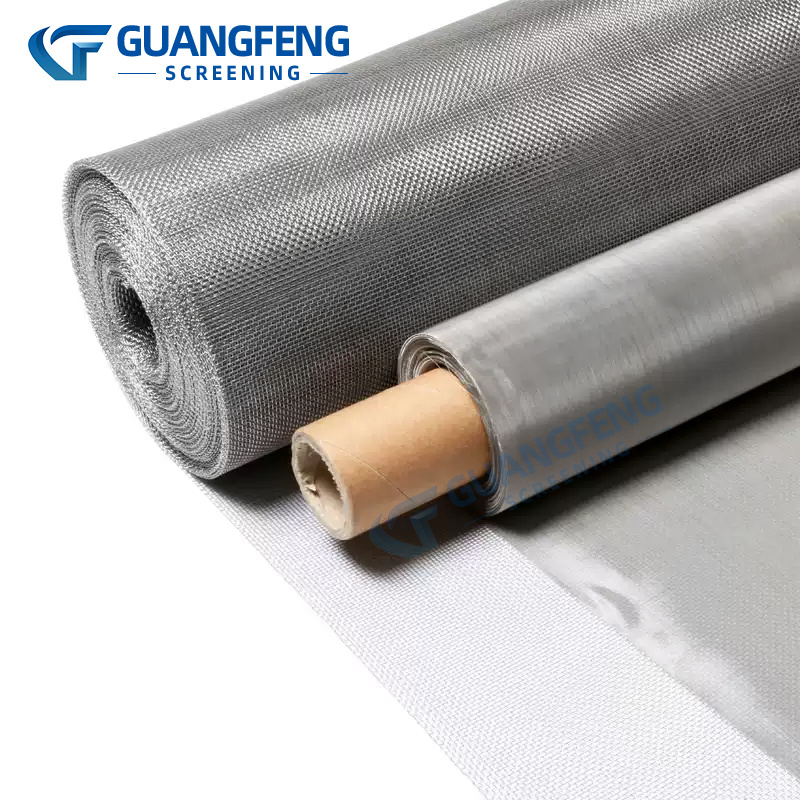

- Material:

Q “What kind of material is used in your stainless steel screen mesh?”

A “Our screen mesh is mainly made of high quality stainless steel, such as 304, 316L, which is rust-proof, corrosion-resistant, and can be adapted to different working environments.”

- Size:

Q “What are the specifications of screen mesh? Can it be customized?”

A “We have a variety of standard specifications, such as mesh size from 10 mesh to 500 mesh, width 0.5 meters to 2 meters, etc. We can also customize special specifications according to your needs. We can also customize special specifications according to your needs.”

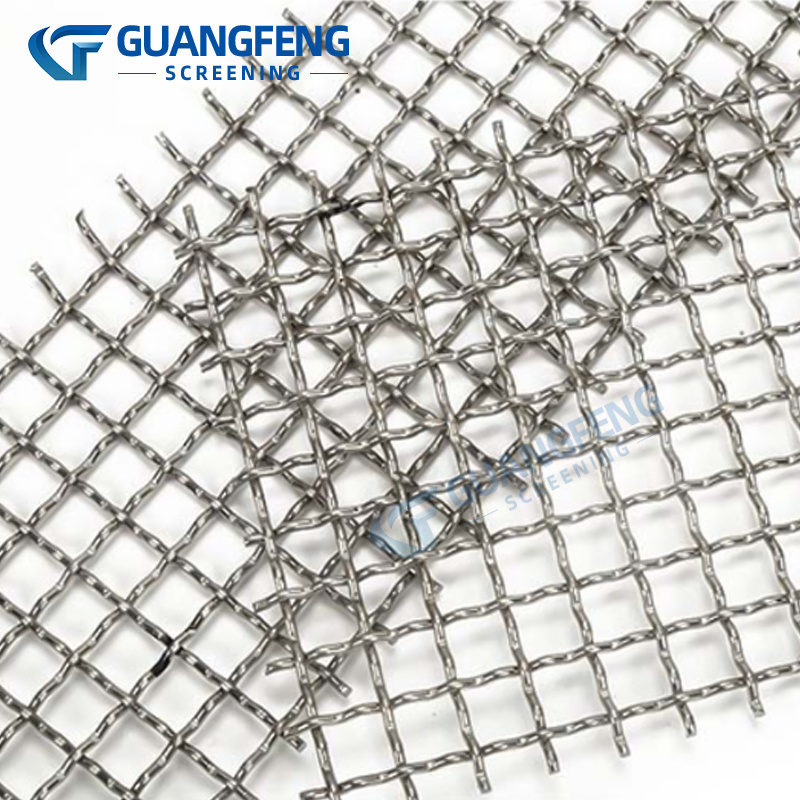

- Product performance:

Q “What is the filtration precision of stainless steel screen mesh?”

A “The filtration precision depends on the mesh number, the higher the mesh number, the higher the precision. For example, 100 mesh screen can filter out particles larger than about 0.15mm.”

Production and processing issues

- Production cycle:

Q “How long will it take to ship after ordering?”

A “Conventional products will be shipped within 15-20 working days after receiving the payment, and customized products will take 20-30 working days, depending on the order quantity.”

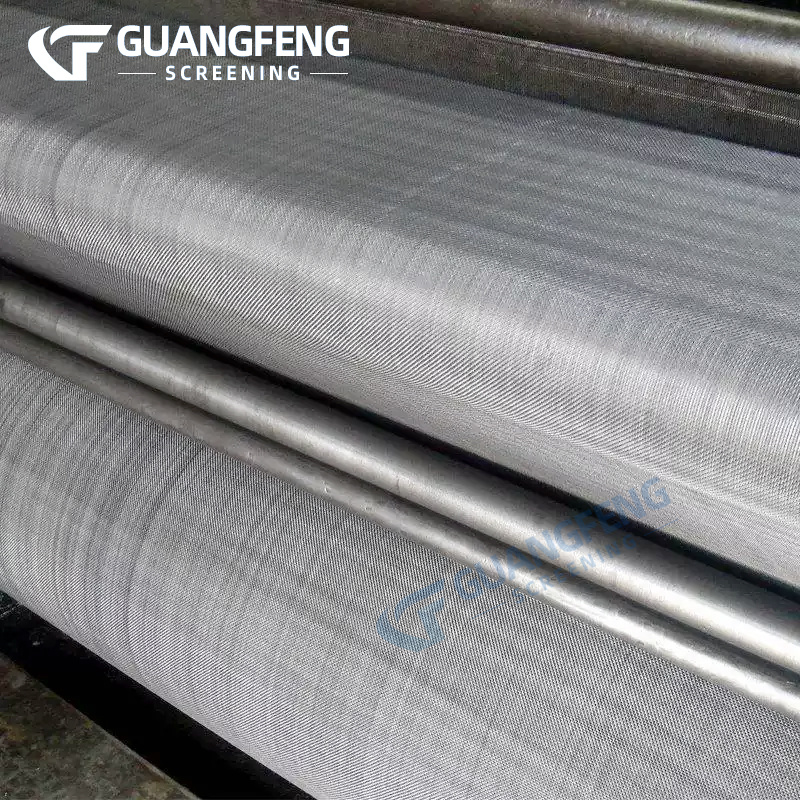

- Processing technology:

Q “How are the screens produced?”

A “We adopt advanced weaving or welding technology, through drawing, weaving, cutting, welding, surface treatment and other processes to ensure product quality.”

Application and installation issues

- Application:

Q “What industries are stainless steel screen mesh applicable to?”

A “Widely used in mining, chemical, food, pharmaceutical, construction and other industries, such as mining ore screening, chemical liquid filtration.”

- Installation method:

Q “How to install the screen?”

A “Installation needs to be based on the use of the scene and equipment to choose the appropriate method. For example, if used in vibrating screen, the screen frame should be fixed first, and then the screen mesh should be tautly fixed with special fixture.”

After-sales and service issues

- After-sales service:

Q “How can I get help if I have problems in using it?”

A “You can contact our customer service team at any time, provide product information and problem description, we will provide timely solutions.”